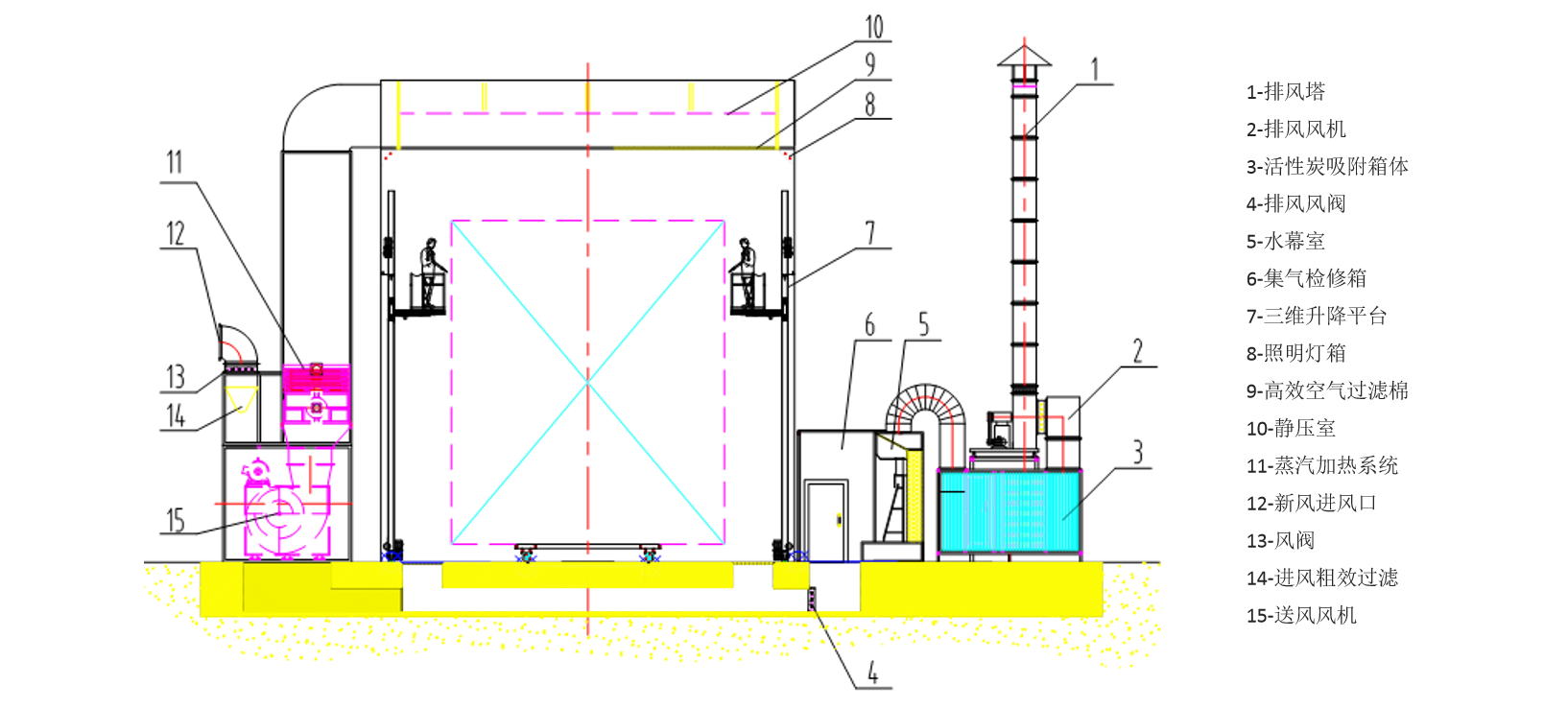

The pumpless water curtain painting room uses the exhaust fan to directly lift the water in the water tank to form a circulating water curtain. It does not need a water pump spray system, and its spray purification efficiency reaches 99%. 5 μ The removal rate of hydrophilic dust above M is not less than 96%, and there is no need to change water frequently and the pipeline will not be blocked.

Jiutong non pump water curtain painting room has the advantages of simple operation, stable operation, durability, high purification efficiency, good painting effect, environmental protection, etc. its room structure can be telescopic, fixed and movable, and can be designed according to the actual situation of customers, with strong flexibility. Project cases: Qingdao CIMC refrigerator manufacturing, Baotou Guodian power, Langfang Zhongchen petroleum equipment, Liaoning Huarong heavy industry machinery, etc.

无泵水幕喷漆房7.JPG

High purification rate of paint mist: unique structure, reasonable purification method, and multi-stage continuous purification. The removal efficiency of paint mist particles and dust generated by grinding is up to 98%

Stable operation: all steel frame structure, double mechanical drive, two-level safety limit, no other system components except exhaust fan and pipeline, safe and stable operation performance

Convenient installation: no civil foundation such as pit is required, and the installation position is unlimited; Advanced modular design, high degree of assembly and fast installation; Non standard design is available

Convenient maintenance: there is no complicated accessory device, and the routine maintenance does not need to be maintained as often as the dry-type paint booth, nor does it have a great impact on the air supply and exhaust effect

No waste water discharge: it has strong adaptability to the water quality. Even the water containing a large amount of paint residue will not block the inside of the equipment in the circulation process and will not affect the purification effect of paint mist

Exhaust gas emission standard: the exhaust gas emission and operating conditions shall meet the national environmental protection standards (GB / T19001-2000 (I d t IS09001: 2000)

The non pump water curtain painting room is widely used in: environmental protection painting of complete machines or parts in machinery, automobile, aviation, aerospace, military industry, railway, motor, construction, water pump, machine tool, furniture and other industries

|  |  |  |  | ||

In the working state of the pump less water curtain painting room, the air-conditioning blower, exhaust fan and circulating pump are started. The outdoor fresh air is purified by the air inlet and sent to the static chamber by the air-conditioning blower. The filter top cotton at the bottom of the static chamber equalizes the air flow and blocks the solid dust. The clean air enters the room in a laminar flow mode, forming an orderly air flow around the work, so that the residual paint mist of the paint spray does not disperse around, so as to protect the labor safety of the operators and workers. Under the action of the air flow, the air flow passes through the water spinner in an orderly manner. The water spinner atomizes the water into fine water droplets, fully washes the air containing the paint mist, separates the paint mist from the air, and achieves the purification effect. The treatment of the paint mist is to use a water spinner to atomize the water and wash the air to purify the paint mist. The structure is simple, there is no clogging problem, the maintenance is small, and the paint mist treatment efficiency is high, up to 99.5%. The waste gas treated by the water spinner paint mist is discharged into the atmosphere by the chimney under the action of the exhaust fan, so as to ensure that the environmental protection technical requirements for industrial three wastes emission are met.

The non pump water curtain painting room adopts profile steel as the framework, and the framework is lined with PVC wear-resistant and anti-corrosion curtain fabric, which is beautiful and smooth.

|  |  |  |  |

| Door frame | Canvas support net | Scissor telescopic mechanism | Flame retardant PVC canvas | Drive mechanism |

It is made of industrial profiles and is directly driven by the drive motor. It is the key to the stable movement of the whole telescopic mechanism. The door frame is provided with a switch button and a travel switch to automatically control the expansion and contraction of the door | Apart from the door frame, the rest parts are canvas support net, which is the framework for installation and connection of flame-retardant canvas. It is composed of multiple groups of profile skeleton, and the whole relatively independent skeleton is connected together through a scissors type expansion mechanism to form a stable whole | The two canvas support nets are connected by a scissor type telescopic mechanism, whose structural size determines the amount of expansion and contraction. At the same time, a set of scissor type telescopic mechanism is arranged at the upper and lower sides of each side to ensure that the upper and lower sides can achieve expansion and contraction at the same time, and a synchronous motion mechanism is formed between the two through a connecting rod | Industrial flame-retardant PVC canvas is used between the entire grid, which is the "wall panel" that forms a relatively closed operation room and also the "room" that ensures the orderly flow of air. During installation, one piece of industrial canvas is used for every two support nets | The drive part adopts a reduction motor, which is transmitted to multiple long shafts, and then is synchronously transmitted to the driving wheels on both sides by the sprockets at both ends of the long shaft. The whole drive adopts three-level protection for forward and backward: two-way two-level travel protection, and the rail terminal is set with limit stops; There are control boxes on both sides of the door post, which is easy to operate; A running warning light is set on the top of the spray chamber. The reducer adopts K series of Dongfang transmission: helical gear - spiral bevel gear reduce |

The painting system of the pumpless water curtain painting room is composed of high-pressure airless painting pump, pneumatic mixer, paint filter and pipeline. It is installed in the paint pump room (paint supply room) and connected with the painting room by pipeline

| Paint supply room One (5.5m) is installed under the platform of the air supply system × 2m × 3m(L × W × H) Paint supply room. Equipped with exhaust fan, the exhaust volume shall not be less than 10 times / min, and explosion-proof exhaust fan and lighting shall be adopted. Ground wires shall be buried in the paint supply room to prevent fire caused by static electricity; In order to facilitate the painting operation, compressed air quick connectors are set on both sides of the paint booth |

| Spray gun American Graco manual high-pressure airless spray gun is adopted, with ergonomic design and strong comfort; Elliptical insulated handle, high safety; The structure design is compact and reasonable, with mobile hose, flexible operation even in narrow space, and high spraying quality; The spray gun filter is easy to take out and easy to repair, reducing the maintenance time due to nozzle blockage. |

| Robot painting With the rising labor cost and the gradual disappearance of the population dividend, it has become an inevitable trend for robots to replace people. The robot is used to replace the spray painting workers for spray painting, which can avoid the heavy labor of the operators in the harsh working environment, and can ensure the stable surface quality of the workpiece and high production efficiency. |

The paint mist treatment system of the non pump water curtain painting room is composed of exhaust fan, blower, water tank, flashing plate, air water channel, air water separator, water drip plate, paint mist channel, etc

|  |  |  |  |  |

| Blower | Exhaust system | water tank | Air water channel | Gas water separator 1 and 2 | Flashing plate (flashing plate or water curtain) |

Low noise and energy-saving centrifugal fan is adopted, which is made of double-sided air inlet, with novel structure, small volume, large air volume and small vibration. The motor can reduce voltage with the help of three-phase voltage regulator to realize stepless speed regulation, and can adapt to places with frequent air volume changes. The forced draft fan base is set on the steel structure platform at the side of the chamber body, and the structure is firm and reliable without obvious vibration; All air supply pipelines are made of δ 1.2mm high-quality galvanized steel plate undercut production, without welding. Ensure that the pipeline is formed without deformation; Install damping or elastic shock absorber at the bottom of the fan, and design noise reduction room to ensure that the system noise is controlled below 85dba | Explosion proof centrifugal fan is selected. The exhaust fan base is made of channel steel, angle steel and industrial profiles welded into a frame. All pipes are made of δ The 1.2mm hot-rolled galvanized plate is made. The noise of the fan is 88DB (a) when it runs empty (without air duct). A noise reduction fan case is set outside the fan, and a spring damper is set under the fan base. After the air duct is connected, the operators can have a good working environment; The exhaust tower is made of galvanized plate and reinforced with wind resistant structure. The size of the exhaust chimney is determined by the air flow speed and the concentration of harmful substances discharged. | The water tank is made of 2mm thick stainless steel plate, 1.5mm thick galvanized steel plate for upper cover plate and flashing plate, and 1.2mm thick galvanized steel plate for side wall plate, rear wall plate, water baffle plate, water collecting tank and guide plate. The surface is sprayed with plastic, which is rust proof and durable. | It is made of stainless steel pipe, and the channel area is made according to the actual situation of the customer | The air-water separator plays a very important role in the non pump water curtain paint booth. When the air-water mixed medium passes through this time, most of the water is separated and falls into the collecting tank, overflows from the overflow tank, and forms a water curtain. Air water separator 1 is made of t1.2 stainless steel plate, which is resistant to corrosion and gas flow erosion. The gap between baffles of gas water separator shall be ≤ 30mm, and shall be folded into a certain diversion angle. The air-water separator 2 is made of stainless steel, which forms a specific angle with the horizontal and air flow direction to further separate the moisture in the air and fall into the water collecting tank. | The water flow plate shall ensure the flatness to ensure that the water curtain is stable and free from flow interruption and turbulence. The water flow plate and water baffle shall be made of stainless steel to ensure their service life. The lower end is a sawtooth structure instead of a general linear structure, which further improves the washing effect; The water film on the water plate is formed by the overflow of the water in the overflow tank above. In order to ensure the uniformity of the water film, the overflow slot is designed into a circular arc shape of Guanghua and inclined inward by 45 ゜, so that the water overflowed from the overflow tank can be uniformly lubricated and will not splash. |

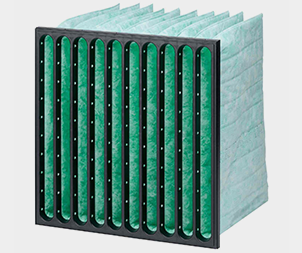

Grade 2-3 filtration is adopted: primary 1-2 filtration and sub high efficiency filtration (top filtration) of air inlet, which is composed of air inlet filter, top filter material, top cotton support net, connecting plate, etc; The sub high efficiency filter material is set at the bottom of the static chamber and supported by the top cotton support net. The top cotton support net is of high-quality C-shaped steel structure. After special rust prevention treatment, it has good rigidity, no corrosion and easy to replace the top cotton;

| Primary filter material |  | Sub high efficiency filter material |

The synthetic fiber filter material product vnf-290 (G3) and the bag filter of the filter section of the air supply system can increase the cotton area of the air inlet by 3-4 times with the cloth bag structure. The adoption of this filter form can reduce the wind resistance, increase the dust capacity and reduce the replacement times | The Dutch "arresters" synthetic fiber filter material cc-600g (F5) is selected as the sub high efficiency filter material, which can filter out all particles that can damage the paint quality, and the dust content is 100% removed to ensure that the air flow passing through the paint booth is evenly diffused and forms a laminar flow state, which conforms to the fire classification standards of European din53438-f1 and American ul900-class1. |

| Exhaust gas treatment systemAn activated carbon adsorption box is installed in the front of each exhaust fan unit and behind the water curtain paint mist washing room in the non pump water curtain paint spraying room. Its function is to absorb the benzene series and other organic solvents in the discharge. The adsorption capacity of benzene series is ≥ 40mg / g, so that the exhaust gas can be discharged up to the standard; The form is divided into activated carbon adsorption device or activated carbon bag filter. First, the activated carbon filter is fixed on the frame, and then installed on the air inlet bracket. It is easy to disassemble and replace. The exhaust gas can be discharged up to the standard after adsorption treatment, meeting the requirements of the national standard GB16297-1996 comprehensive emission standard of air pollutants. |

lightingThe upper and lower rows of lighting devices are set in the spray drying room. The top side lamp group is installed at a 45 º angle, and the arrangement is: 2 × 40W × 2 sides; The waist lamp group is installed in the wall panel at intervals, and the arrangement is: 2 × 40W × 2 lines. All light boxes adopt δ 1.2 the galvanized plate shall be made and sprayed with white paint, which is beautiful and generous, and can prevent the appearance of rust. The lamp tube adopts explosion-proof Philips high-efficiency light source, which is safe, energy-saving and easy to maintain. The ballast adopts the special electronic ballast for the spray booth, so as to ensure that the light intensity of each spray booth is ≥ 800Lux and meet the spraying operation of each end face of the workpiece. The light box and the wall panel are connected by small angle iron, and the light box is equipped with a detachable frame for easy maintenance. |  |

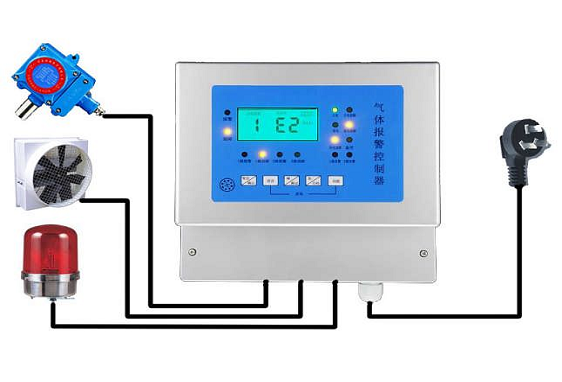

| Safety alarm systemTo ensure safe use, the chamber is equipped with drb-105 dual controller dual detector combustible gas concentration detection device. When the solvent concentration reaches 25% of the explosion limit (which can be freely set), the alarm will be given immediately; Telescopic room operation warning and fault alarm shall be set at the top of the spray chamber |

Electronic control systemThe components of the electronic control system of the non pump water curtain painting room shall be well-known brands such as Omron, Siemens and Schneider. The main circuit shall be provided with protection functions such as overcurrent, overload, short circuit and short circuit to ensure high reliability and low failure rate of the electrical control system. The line design is reasonable, with short-circuit protection, overload protection and other functions and reliable grounding protection system. PLC programming can control the whole equipment. The distribution control cabinet in the system is sprayed with plastic on the surface, which is beautiful and generous. In order to ensure the sequence and safety of the work, the interlocking of the lower workpiece to the painting is adopted. Any door of the spray booth shall be equipped with operation warning light and emergency stop button, and the door shall be interlocked with the spray gun. When the warning light is on during painting, the painting system will automatically stop if any door is opened intentionally or unintentionally. Emergency stop switch shall be set in the control cabinet and painting room. |  |

| Serial number | name | Company | numerical value | parameter |

|---|---|---|---|---|

| 1 | Paint booth type | Mobile pumpless water curtain paint booth | ||

| 2 | Equipment size | mm | 10000*6000*6000mm | Designed according to workpiece size requirements |

| 3 | Gate size | mm | 6000*6000mm | |

| 4 | wind speed | m/s | ≥0.4 | No load |

| 7 | Exhaust air volume | m³/h | 60000m³/h | Explosion proof motor |

| 8 | Fan power | KW | 37 | |

| 9 | Lighting power | KW | 2.6 | Explosion proof lamp |

Note: the equipment dimensions are for reference and can be designed and manufactured according to the customer's product dimensions.

If you want to customize it, you can click this text

1. It has double certificates of ISO9001 quality management system and environmental management system to protect the product quality

2. In 2014, it was listed as a high-tech environmental protection coating enterprise recognized by aerospace enterprises

3. National high-tech enterprise and safety production standardization certification company

1. Complete the technological innovation of "coating industrial robot", "coating waste gas treatment system", "environmental protection recycling abrasive recovery system" and "composite strong sand absorption base plate technology"

2. Obtained 8 national patents and possessed independent intellectual property rights

3. More than ten years of experience in the application and implementation of equipment (standard and non-standard) and production line customization projects, which is trustworthy

1. Not practicing fraud and sticking to quality is the first lifeline of the enterprise

2. The source equipment manufacturer has a warranty period of two years (excluding vulnerable and consumable parts), and the price is guaranteed on the basis of quality assurance

1. Have a professional trained construction team to complete the project with quality assurance

2. The after-sales department implements 7 * 24-hour telephone or online service

3. It has after-sales service stations in Beijing, Shandong and Zhejiang, and has a perfect after-sales system with high troubleshooting efficiency