Spray painting and plastic spraying are mainly used in light rail, high-speed railway, ships, aircraft, bus body, bus body, special vehicle, construction machinery, mining machinery, valves and other industries.

Coating production line of wind power industry

Rail transit coating production line

Painting production line for structural parts

Powder spraying line for robot structural parts

Special vehicle coating production line

Air suspension transportation equipment and ground transportation complete equipment

Electrophoresis equipment, sand blasting / shot blasting equipment, cleaning equipment

Telescopic room and transverse exhaust room

Dry spray booth, wet spray booth and paint supply system

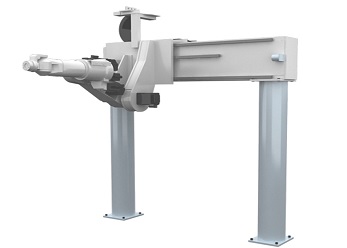

Loading and unloading robot, sandblasting / shot blasting robot, painting / powder robot

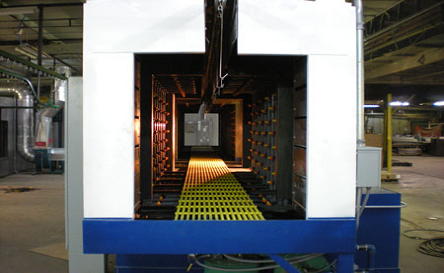

Natural gas / electric heating / natural gas infrared radiation / steam paint baking room

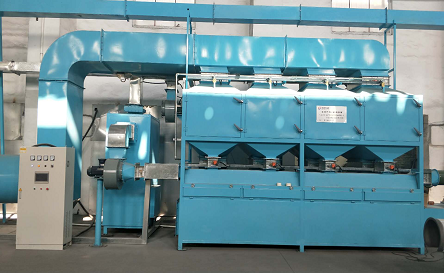

Cartridge type dust collector and bag type dust collector

Activated carbon + RCO, zeolite runner + catalytic combustion system, mobile VOCs waste gas treatment equipment

The combination form of coating line is designed according to different product materials, processes, coating types, workpiece surface conditions and other requirements, and the pretreatment methods and spraying forms are also different.

Pretreatment: 1. Dry treatment method (sand blasting and shot blasting); 2. Wet treatment method (immersion type, spray type).

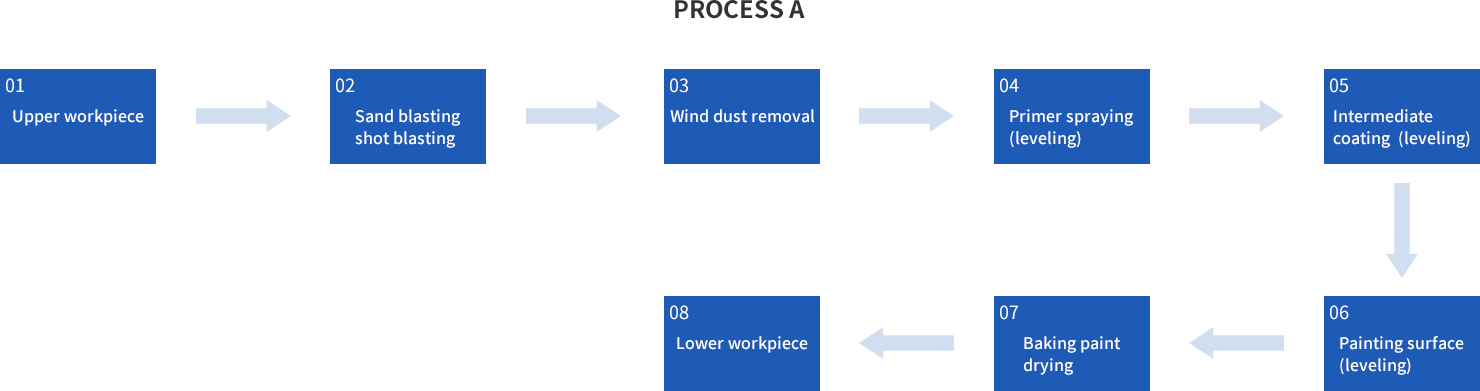

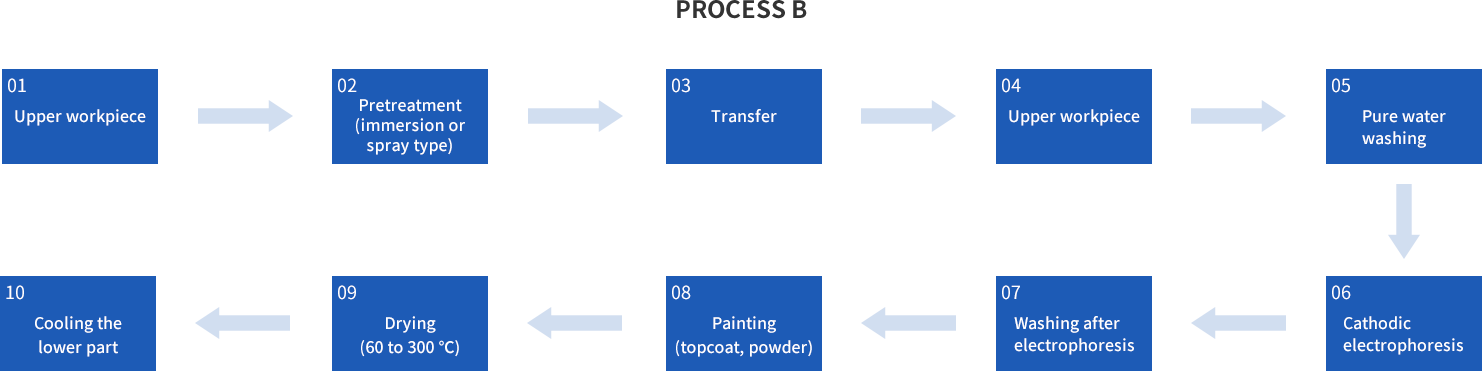

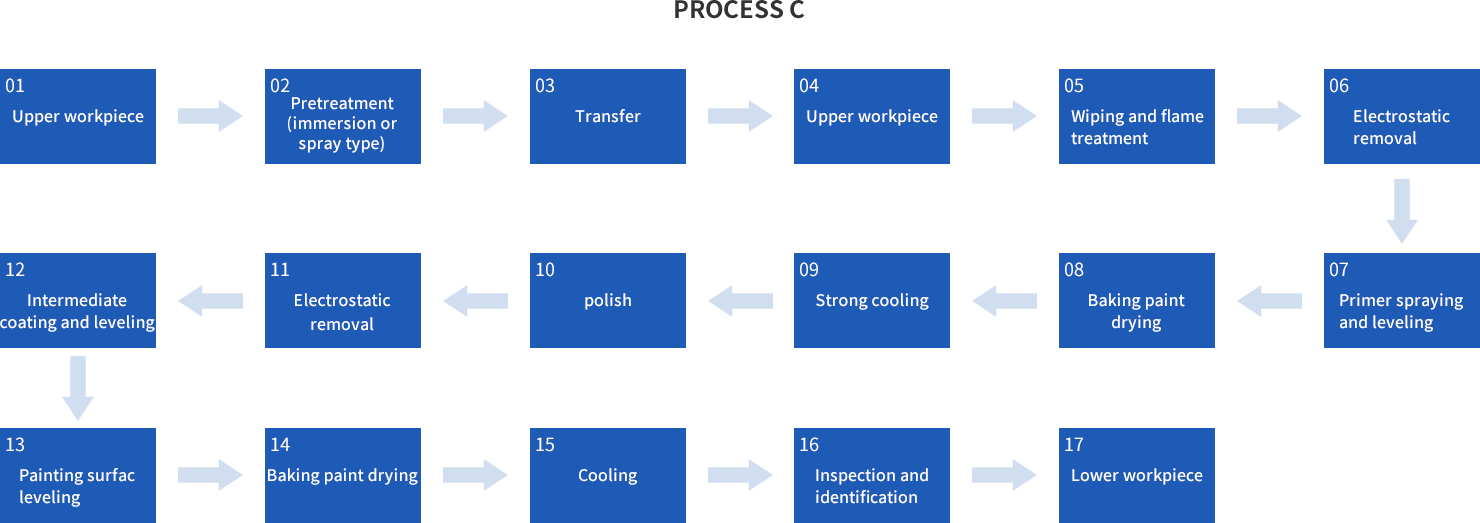

Antirust coatings are different: 1. Painting; 2. Powder coating; 3. There are three representative forms of organization of electroplating (galvanizing, gold plating, silver plating, etc.) coating line, and the process flow is as follows:

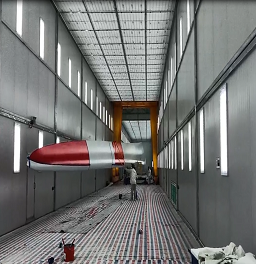

This method adopts mechanical (dry) surface pretreatment, and uses sand blasting (shot blasting) room and shot blasting machine equipment to remove rust and oil for the workpiece, change the surface roughness of the workpiece, increase the adhesion of the surface to the coating, and then spray paint and dry (this method is a 3-spray-1-drying process, which can be changed to 2-spray-1-drying and 2-spray-2-drying according to the actual situation. 4 and 5 are optional processes in the process).

The workpiece in this spraying line is generally transported by electric rail car or crown block. The spraying line is mainly used for metal workpieces, equipment and steel plates with thick materials and large workpieces, such as cast forgings and steel structural parts. 1 spraying and 1 drying are generally suitable for equipment with low surface requirements (generally not recommended). Generally, due to the large and heavy workpieces and low production capacity, sand blasting (shot blasting) and dust removal are handled in the sand blasting room. The spraying of primer, finish coat and drying are all carried out in the spraying and drying integrated room.

|  |  |

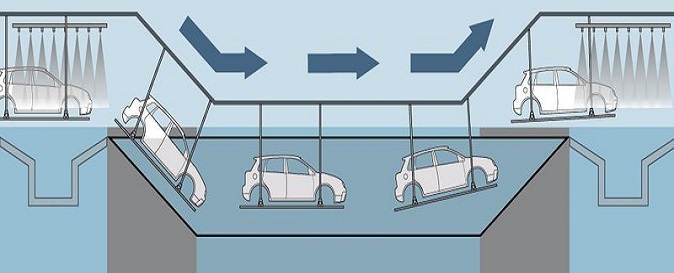

The pretreatment of the electrophoretic coating line mostly adopts the immersion and spraying treatment methods (or the combination of spraying and dipping). Its main purpose is to achieve the purpose of oil removal, degreasing, rust removal, water washing and pure water washing through the chemical liquid (sulfuric acid and nitric acid) in the form of immersion or spraying, and the chemical reaction with the oxide and grease on the surface of the workpiece. Cathodic electrophoresis or anodic electrophoresis is adopted for electrophoresis. Compared with anodic electrophoresis, cathodic electrophoresis is more mature in technology, and the adhesion and corrosion resistance of paint film after electrophoresis are stronger than that of anodic electrophoresis. The decorative paint after swimming can be sprayed or decorative paint. The pre-treatment of the conveying system generally adopts self-propelled hoist or stacked conveying equipment, and the transfer line after the pre-treatment generally adopts the ground chain skid, suspended conveying chain, head office hoist and other conveying methods. The specific needs shall be determined according to the workpiece conditions. The main determinants are the size, shape, weight and material of the workpiece.

|  |

|  |  |

The painting and coating line is represented by the plastic parts process. Most of the pre-treatment methods are spray treatment (some metal parts are immersed or spray and immersion). The main purpose is to achieve the purpose of oil removal, degreasing, water washing and pure water washing through the chemical liquid (sulfuric acid and nitric acid) and the oxide and grease on the surface of the workpiece by soaking or spraying. The surface coating is decorative paint materials such as anti-corrosion paint, color paint and varnish. In consideration of high-temperature deformation of plastic parts, the film-forming temperature of the paint is generally about 50-80 ℃. The pre-treatment of the conveying system generally adopts light hanging chain, conveyor belt and mesh chain conveying equipment, and the transfer line after the pre-treatment generally adopts ground chain skid, hanging conveyor chain and other conveying methods. The specific needs shall be determined according to the workpiece conditions. The main determinants are the size, shape, weight and material of the workpiece.

|  |

|  |  |

It can be divided into air suspension conveying equipment and ground conveying complete equipment

Electrophoresis equipment, tank, chamber, platform, oil removal device, iron dust removal device, silane or phosphating slag removal device, mixing and spraying pipeline system, shaft sealing system, temperature control system, lighting system, air supply

The surface of the workpiece can be cleaned of oxide scale, burr, welding slag and rust, so as to meet the process and surface strengthening requirements of coating roughness