Electrostatic powder spraying room is also called plastic spraying room. Its spraying principle is to use corona discharge phenomenon to make powder coating adsorb on the workpiece, with high efficiency (coating utilization efficiency of more than 98%) and strong economy (one-time covering, no sagging; no solvent; easy cleaning, reduce maintenance cost; reduce fire risk probability, reduce insurance expenses) Ecological and environmental protection (elimination of toxic and flammable solvents; compliance with laws and regulations on water source and air pollution control; safer and healthier operation site); energy saving (no need to provide or heat supplementary air; no need to flash dry); high quality coating (Durability / toughness / abrasion resistance / chemical corrosion resistance / high gloss, electrical insulation).

机器人喷粉视频.mp4

High powder utilization rate: the large cyclone powder recovery system, which is not sprayed on the workpiece, has a powder recovery rate of 98.9%, saving hundreds of thousands of costs each year

Good coating performance: compared with liquid coating, the coating with the same thickness is more resistant to acid, alkali and salt, with good anti-corrosion effect and high adhesion

Good spraying effect: high powder coating rate, no dead angle, uniform coating, no color difference and no falling off

Safety and environmental protection: no solvent is used to effectively improve the working conditions of workers, no atmospheric solvent pollution, and the fire hazard caused by solvent can be avoided

Simple process flow: one layer of powder coating can replace several layers of ordinary liquid coating, reducing production process, process, saving man hours, site, energy consumption and other costs

No worries for acceptance: flame induction detection + flameproof valve, explosion-proof port, explosion-proof port, etc. are installed inside, which can pass the security inspection and acceptance; The secondary recovery is equipped with 0.1um high-precision filter element, and the powder is less than 0.03g/m ³, No worries about environmental impact assessment

The electrostatic powder spraying room is widely used for the surface painting and baking of workpieces in such industries as ship pipe parts, wind power blades, towers (towers), wind power gear boxes, wind power bearings, wind power hubs, chemical equipment, petroleum equipment, aerospace, printing machinery, automobile, machinery, hardware and FRP products.

|  |  |  |  | ||

| Principle of powder spraying in electrostatic powder spraying room | Principle of powder recovery in electrostatic powder spraying room |

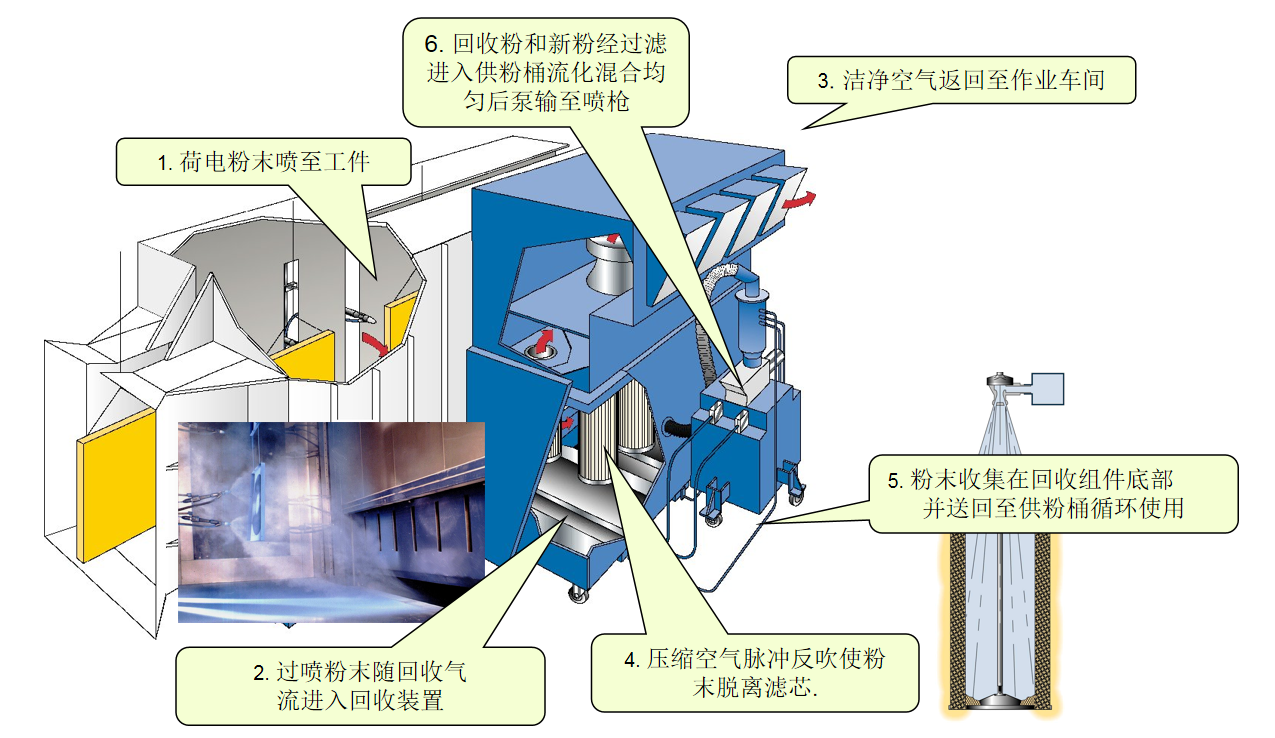

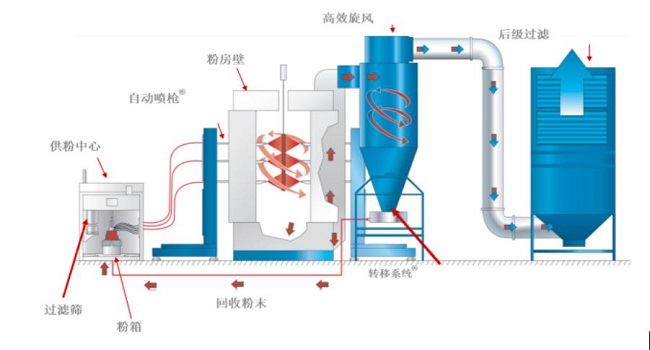

The powder gun is connected to the negative electrode, and the workpiece is grounded (positive electrode). The powder coating is sent to the spray gun by the powder supply system through compressed air. The high voltage generated by the high-voltage electrostatic generator is added at the front end of the spray gun. Due to corona discharge, dense charges are generated nearby. When the powder is ejected from the nozzle, it forms a circuit to form charged coating particles. It is attracted to the workpiece with opposite polarity by the electrostatic force. As the sprayed powder increases, The more the charge is accumulated, when the thickness reaches a certain value, the electrostatic repulsion will not continue to absorb, so that the whole workpiece can obtain a certain thickness of powder coating, and then the powder is melted, leveled and solidified by heat, that is, a hard coating film is formed on the surface of the workpiece. | In the process of powder spraying, the powder not absorbed by the workpiece falls to the bottom of the powder spraying room. The mushroom head back blowing device at the bottom of the powder spraying room blows the powder to the recovery port. The powder is sucked into the large cyclone separator with the air flow for primary recovery. Under the action of the cyclone, the powder and air are separated. At this time, 96% - 98% of the separated powder falls into the powder collecting drum, and the powder in the powder collecting drum is pumped to the vibrating screen under the action of the powder pump, After being filtered by the vibrating screen, the powder is automatically returned to the powder supply barrel for recycling. During the operation of the large cyclone, about 1% - 4% of the ultra-fine powder enters the secondary powder recovery filter through the tuyere at the top of the large cyclone for separation. The clean air is discharged to the operation workshop or to the atmosphere. The ultra-fine powder is absorbed by the filter element. The high magnetic pulse valve inside the filter element works intermittently to blow the ultra-fine powder on the filter element to the bottom powder collector. The recovered ultra-fine powder cannot be recycled and cleaned regularly. |

Working principle diagram of powder spraying room

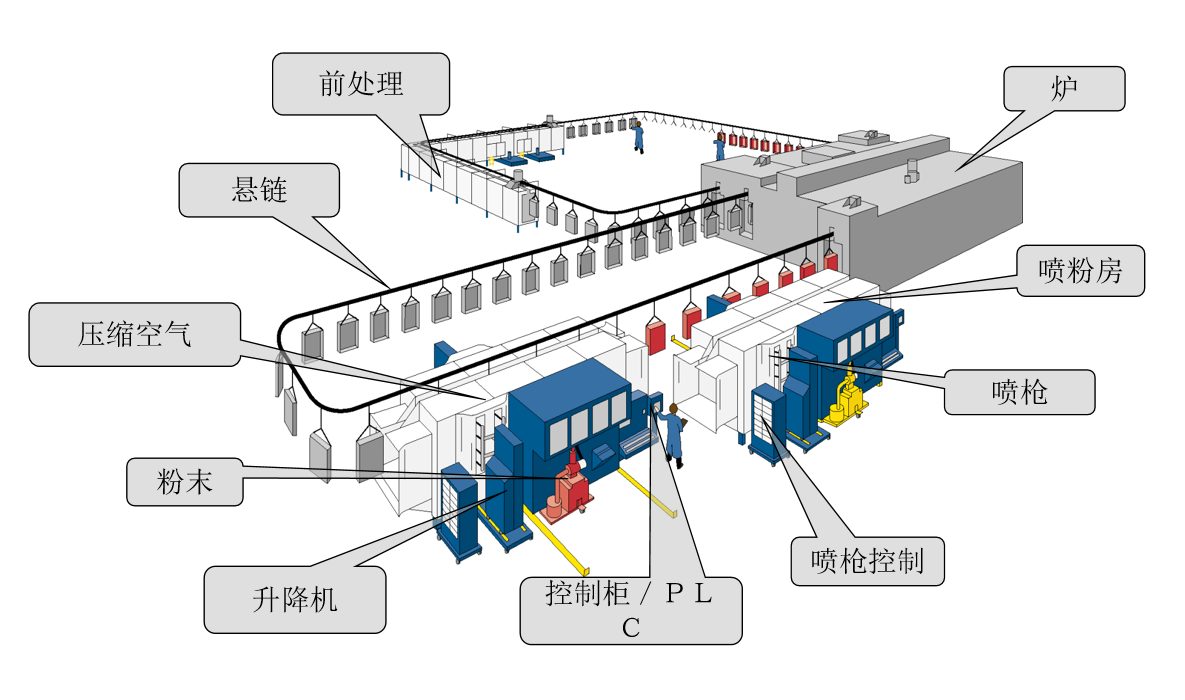

The electrostatic powder spraying room is mainly composed of chamber body, exhaust system, powder supply system, spraying reciprocating machine, automatic spray gun and manual powder spraying gun combination, powder spraying robot system, manual supplementary spraying station, powder recovery equipment, lighting system, explosion-proof system, conveying system, electric control system, security system and other process equipment.

Structural drawing of powder spraying room

The body plate of the electrostatic powder spraying room is made of 0.5mm thick SUS304 stainless steel plate, the outer plate is made of 0.5mm thick color steel plate, and the inner and outer plates are filled with 50mm thick insulating rock wool. The volume weight of rock wool is 100kg / M ³, The inner and outer surfaces of the chamber are made of PP to ensure the insulation of the chamber, and the surface is free of powder adsorption to ensure the powder recovery efficiency; The steel frame is made of high-strength section steel, and the chamber door is electrically operated. It is interlocked with the catenary system to realize the automatic entry and exit of workpieces. At the same time, manual operation buttons are set to realize manual opening and closing. |  |

| The fans and motors of the air supply and exhaust system of the electrostatic powder spraying room shall be made of well-known domestic brands. In the design, high-efficiency and energy-saving equipment shall be selected, the cost performance of the equipment shall be fully considered, and the relevant environmental protection requirements shall be met. The fan shall be installed with shock absorption to ensure that the noise at the production site meets the relevant environmental regulations. The air supply and exhaust pipes shall be galvanized sheet with a thickness of not less than 1.0mm. After installation, no leakage shall be ensured. The exhaust pipe can be shared with the primer polishing room, which is 3 meters higher than the plant and 15 meters higher than the ground. The air supply and exhaust system shall meet the requirements of indoor ventilation times, and the negative pressure in the room shall not be less than 50pA to prevent the exhaust gas from overflowing. |

The powder supply system of the electrostatic powder spraying room includes the placing platform of the powder pipe of the powder pump, the touch screen, the automatic powder feeding device and the powder particle detector. The powder supply system shall be able to change powder conveniently, quickly and automatically, and the powder supply system shall be free of powder overflow. Party B shall provide the scheme description of the powder supply system, and the design and construction can only be carried out with the consent of Party A. |  |

|  |  |  |

| Spraying reciprocating machine | Manual powder gun | Automatic powder spraying gun | Powder spraying robot system |

It has linear reciprocating motion in both vertical and horizontal directions. The speed of reciprocating motion can be adjusted. The design adjustable range of speed regulating wheel is 6 "- 24" on average. It has strong bearing capacity and can be installed with multiple sets of spray guns. | The manual powder spraying equipment can be selected by the user, including one set of electrostatic control box, one set of built-in high-voltage electrostatic generator, one detachable stainless steel powder supply barrel (matched with manual gun), one set of powder pump, powder pipe and low-voltage cable. Simple operation, automatic and rapid color change, better powder performance, PCC precise charging control mode and super corona ring technology improve quality, accurate powder usage, and flexible capacity expansion. | Convenient control of multiple spray guns, simple operation of the control panel, and application parameters can be set for up to 12 spray guns at the same time; Each spray gun can be activated and controlled independently, which is most suitable for vertical aluminum profiles, coils and other spraying applications requiring multiple spray guns; Most suitable for standard spraying line; Accurate powder usage improves the uniformity and consistency of film thickness, which can be easily controlled by even beginners. Based on application experience, three application programs are preset for spraying flat workpieces, large materials and back spraying elements; Automatic spray gun can achieve the highest powder loading rate and perfect spraying effect in any application. It is an ideal choice for rapid color change. | The robot has a separate OP control box. The control box is equipped with a 10 inch display screen. The control box can realize the switching of automatic, manual and analog modes of the machine. In the automatic mode, the robot performs automatic powder spraying under the automatic operation condition of the production line; In manual mode, the operator can spray powder by inputting the workpiece model; In the simulation mode, the operator inputs the model of the workpiece, and the robot only walks on the trajectory without spraying powder. The robot has the ability to identify empty hangers. When there are empty hangers entering, the robot will give an audible and visual alarm. The robot and the production line shall have enough safety interlock points to ensure the safety of the production process. |

| Manual supplementary spraying stations are set on both sides of the electrostatic powder spraying room. The size and position of the stations are reasonable. According to the robot simulation spraying trajectory, it is ensured that the manual spraying can cover the positions that the robot cannot spray. The rationality of the chain speed and the manual supplementary spraying speed shall be fully considered in the design to ensure that the station design meets the line speed requirements. At the same time, the height of the station shall be set reasonably to cover manual supplementary spraying of all workpieces and facilitate manual operation. |

The electrostatic powder spraying room adopts the large cyclone recovery and secondary recovery system. The noise of the whole system meets the requirements of the production workshop and is not more than 75db. The bottom of the powder spraying room shall be equipped with a powder blowing device to prevent powder accumulation, and equipped with professional powder room cleaning tools. The powder recovery rate of the recovery system is not less than 98%; The recovery system shall be provided with explosion vent, and the fan motor shall be controlled by frequency conversion; The secondary recovery system shall ensure that all plastic powder does not leak to the workshop; The powder changing time shall be no more than 45min; Simple, convenient and thorough operation; There is no cross contamination after powder change. The coated filter element and rotary wing unit are used for ultra-clean filtration. The filtered air is discharged to the outside of the workshop through the exhaust pipe of the grinding room, with long service life and low noise. |  |

Large cyclone recovery system |

Primary pulse filter element recovery system |

Ultimate filter |

| Explosion proof systemThe explosion-proof system includes dust detection device, flame alarm device, automatic fire extinguishing device, gas locking and ash unloading device, etc. When the dust detection device detects that the dust concentration in the powder spraying room is abnormal, close all powder guns to supply powder, and give an audible and visual alarm; When the flame alarm device detects that there is a flame abnormality in the curing room, it can immediately start the automatic fire extinguishing device and the gas locking and ash unloading device, cut off the natural gas supply and dust return, and ensure that the flame does not expand. |

lightingThe illumination of the interior lighting system of the room is greater than 300lux. Explosion proof lamp tubes are used for lighting and dust covers are installed. The electrical components are of explosion-proof type. Common models and installation methods are selected to ensure the convenience of subsequent maintenance of the interior illuminance meter of the room. |  |

| Control systemThe control system of electrostatic powder spraying room can realize both automatic control and manual control of the equipment. During automatic control, ensure that the catenary system, exhaust system, electric door or pneumatic type can be linked to realize the automatic and normal flow of equipment, and set sufficient safety interlocks to ensure the safety of the workpiece during operation and prevent the workpiece and the chamber door; Manual control shall ensure that all equipment can be started and stopped manually to ensure the convenience of maintenance of all equipment. Emergency stop button shall be set. After pressing the emergency stop button, all equipment will stop operation. |

Stacking chain conveyor systemThe stacking chain conveyor covers the upper part area, primer polishing room, soot blowing room, powder spraying room, curing room, strong cooling room and lower part area. The whole logistics chain is transported by one chain, and the drive motor is controlled by frequency converter, which is an internationally famous brand. The load-bearing gantry and hanger of the stacking chain conveyor system shall be designed according to the site conditions and workpiece style of Party A to ensure beauty, convenience, durability and convenient maintenance. |  |

| Serial number | name | Parameters / specifications |

|---|---|---|

| Size of electrostatic powder spraying room(mm) | 6000×3000×2200 | |

| 1) | Working opening size of powder spraying room(mm) | 4㎡ |

| 2) | Design wind speed of working opening of powder spraying roomm/s | 0.5 (side wind speed is not less than 0.3) |

| 3) | Design exhaust volume of powder spraying room m³/h | 9000 |

| 4) | Model of exhaust fan | 4-72No5A |

| 5) | Air volume of exhaust fan m³/h | 9500 |

| 6) | Exhaust fan power kW | 7.5 |

| 7) | Air pressure of exhaust fan Pa | 1730 |

| 8) | Wind speed in exhaust duct m/s | >15 |

| 9) | Compressed air consumption m³/min | 0.6~2 |

| 10) | Total power of recovery unit kW | 8 |

| 11) | Equipment noise | <85 Decibel |

1. It has double certificates of ISO9001 quality management system and environmental management system to protect the product quality

2. In 2014, it was listed as a high-tech environmental protection coating enterprise recognized by aerospace enterprises

3. National high-tech enterprise and safety production standardization certification company

1. Complete the technological innovation of "coating industrial robot", "coating waste gas treatment system", "environmental protection recycling abrasive recovery system" and "composite strong sand absorption base plate technology"

2. Obtained 8 national patents and possessed independent intellectual property rights

3. More than ten years of experience in the application and implementation of equipment (standard and non-standard) and production line customization projects, which is trustworthy

1. Not practicing fraud and sticking to quality is the first lifeline of the enterprise

2. The source equipment manufacturer has a warranty period of two years (excluding vulnerable and consumable parts), and the price is guaranteed on the basis of quality assurance

1. Have a professional trained construction team to complete the project with quality assurance

2. The after-sales department implements 7 * 24-hour telephone or online service

3. It has after-sales service stations in Beijing, Shandong and Zhejiang, and has a perfect after-sales system with high troubleshooting efficiency