The filter cartridge dust remover is composed of a filter cartridge as a filter element or a pulse jet dust remover, which can effectively filter the dusty air, with an efficiency of 99.999% and a filtration accuracy of 0.3% after PTFE film coating μ m. Good air permeability, dust is not easy to agglomerate; Flexible installation mode, upper installation, oblique insertion, lifting and side installation; Modular design, fast loading and unloading; Suitable for high concentration working conditions

The nine-way filter cartridge dust collector adopts the internationally popular torret type dust collector structure, which is consistent with the structure of the internationally renowned dust collector "Donaldson". The filter cartridges can be interchanged, either with the American Donaldson filter cartridge or with the domestic filter cartridge. It has the advantages of high filtration effect, non clogging, convenient installation, simple operation, stable operation, small floor area, energy saving and high efficiency. It has been installed in China Shenzhou aircraft Co., Ltd Beijing Lantian glass factory, Hebei runkun Co., Ltd. and other companies apply customized project service is our strong point, and we can provide free design solutions for enterprises.

滤筒除尘器7.jpg

High dust removal efficiency: for different dusts, different filter cartridges and filter materials are used for filtration, and the dust removal efficiency is as high as 99.99%, or 0.3 μ M) dust

Convenient replacement: modular combination, smaller than bag type, can quickly replace and increase the dust removal unit

Simple maintenance: the filter cartridge is designed in an integrated way, and the upper cover is installed and overhauled (the filter cartridge is installed in a 15 ° inclined drawer type, which allows the filter cartridge to be disassembled and replaced), which is convenient for the replacement of the filter bag and has good sealing performance

Energy reduction and consumption reduction: pulse technology, reverse blowing system, one pulse valve can be injected into one row at the same time (the maximum number of filter cartridges in each row is 12), which can greatly reduce the number of pulse valves and reduce energy consumption

Large filtration area: the filter cartridge structure is folded in a cylindrical shape. The filtration area of a standard filter cartridge is 23 ㎡, while the bag type with the same volume is only 1 ㎡

Long service life: the dust baffle at the dust inlet has a buffering effect, and the dust will not directly impact the filter cartridge at high speed. The shake of the filter material is small when cleaning the dust, so that the life of the filter cartridge is much longer than that of the filter bag, and the maintenance cost is low

The filter cartridge type dust collector shall be used for non-ferrous smelting, building materials, electric power, light industry, metallurgy, chemical industry, tobacco, shipbuilding, steel machining, dust recovery, casting, aerospace, industrial power station boilers, heating boilers, etc

|  |  |  |  | ||

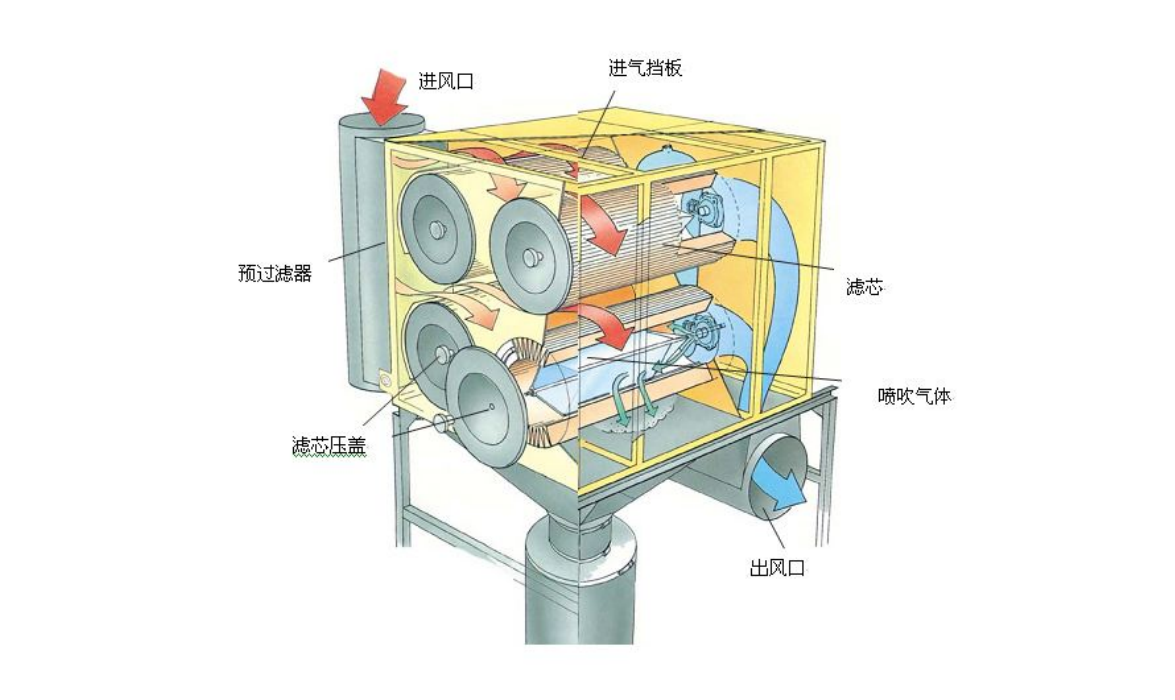

The pulse filter cartridge dust remover is equipped with air inlet, filter cartridge, air outlet, air bag, pulse controller, injection valve, injection pipe, etc. the filter cartridge is made of polyester fiber folded and rolled. Its lower end is closed and its upper end is facing the lower mouth of the injection pipe. After the dust containing gas enters the dust collector from the air inlet, the air flow speed slows down, the coarse particles leave the air flow and settle in the dust collection room. When the fine dust passes through the filter cartridge with the air flow, it is blocked on the outer surface of the filter cartridge, and the clean gas is discharged from the air outlet; When the ash layer on the surface of the filter cartridge is thick, the pulse controller sends a command to open the blow valve, and the compressed air in the air bag is ejected through the blow pipe at a high speed. At the same time, the surrounding air several times the injection volume is induced to enter the filter cartridge, and is ejected from the inside to the outside. The dust on the outer surface of the filter cartridge is blown down into the dust collection chamber, and then discharged by the ash hopper. The dust remover adopts the pulse blowing method, which not only cleans the dust, but also does not damage the filter cartridge, so that the service life of the filter cartridge can be prolonged. The ash cleaning process is automatically controlled by the pulse controller, and can be controlled by pressure difference or time. The dust of the whole room dust removal system is discharged in different areas. The screw conveyor is used to collect the dust and foreign matters at each discharge point for centralized discharge. The dust cylinder can be cleaned regularly, thus reducing the labor load of workers. The dust collector is equipped with an ash storage bucket, which can discharge ash in a centralized manner.

|

|

Structure diagram of filter cartridge dust collector

Structure diagram of filter cartridge dust collector

The structure of the filter cartridge type dust collector is composed of an air inlet pipe, an exhaust pipe, a box, an ash hopper, an ash cleaning device, a guide device, an air flow distribution plate, a filter cartridge and an electric control device.

|  |  |  |

| Box | Filter cartridge | filter material | Air inlet and exhaust pipes |

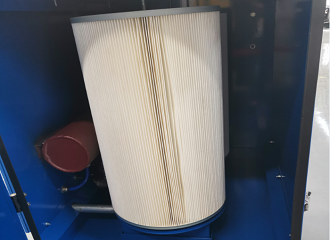

The main body box is made of excellent carbon steel, with air tightness design. The inspection door is made of excellent sealing materials, and kerosene is used for leak detection in the manufacturing process. The air leakage rate is very low. Manhole access door is set at the top to facilitate the installation and replacement of filter materials; The boxes of different specifications can be customized according to the needs. The box is divided into several chambers, separated by partitions, which are airtight to each other and realize off-line ash removal; Each room is equipped with a poppet valve to switch the filtered air flow; The upper box is designed with a certain slope, which is conducive to the smooth drainage of rainwater; The middle box is made of steel plate with thickness of 5mm, and the surface is painted with rust prevention, firmness and durability. | Folded cylindrical, with an outer diameter of 320mm, an inner diameter of 220mm, and a cylinder height of 660mm. The inner and outer parts are supported by metal frames, and the upper and lower parts are fixed by a top cover and a base. The filter area of a standard filter cylinder is 23m2, while the filter area of the same type bag is only 1m2; The arrangement and layout are reasonable, and the horizontal combination is installed, and the upper inlet air and the lower exhaust air are used. This structure is conducive to the introduction of dust containing gas into the filter cartridge carriers in the dust collector room and the uniform distribution. It is also conducive to the falling of the dust that is bounced off in the instant of back blowing and cleaning, and reduces the possibility of secondary adsorption; The lower exhaust structure is directly introduced into the fan through the clean air chamber. The fan motor is floor type, which enhances the stability of the equipment and saves unnecessary waste caused by pipeline connection. | The filter cartridge adopts the new material produced by Donaldson technology. The filter material is 100% polyester fiber with a thickness of 0.80mm; Heat resistant maximum temperature: 80 ℃; Air permeability: 220m ³/ m2/h; Weight: 260g / m2; Filtration precision: 5um-10um;Filtration resistance: ≤ 46pa; Filtration efficiency: ≥ 99.99% | Pulse filter cartridge dust collector air pipe adopts δ 1.5mm galvanized plate undercut fabrication, no welding, anti-corrosion and thermal insulation treatment, compact air duct layout, small air flow resistance, avoid horizontal pipes in pipe design, and minimize elbows; The pipeline is connected by flanges, and asbestos rope is filled between the flanges as the sealing material, which is beautiful and durable. |

|  |  |  |

| Fan | Ash cleaning device | Dust collecting bucket | Control system |

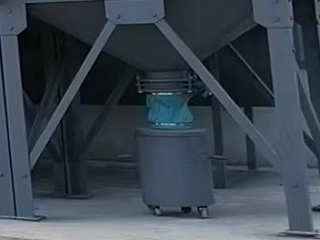

The double suction bkkf explosion-proof centrifugal fan is adopted for the filter cartridge dust collector, which has the characteristics of good performance, high efficiency, beautiful appearance, compact structure, stable operation, and convenient installation and maintenance. The forced draft fan base is welded into a frame with channel steel and angle steel industrial profiles to bear the weight and vibration of one forced draft fan; Air supply pipes are all made of δ 1.2mm high-quality galvanized steel plate undercut production, without welding, to ensure that the pipeline is formed without deformation; A damping or elastic reducer is installed at the bottom of the fan. At the same time, we have designed a fan noise reduction room to ensure that the system noise is controlled below 75dBA. | The dust remover adopts the pulse back blowing method. Its working principle is: when the pulse controller sends a signal, the exhaust port of the pulse control valve is opened, the gas outside the back pressure of the pulse valve is released, the pressure difference is generated on both sides of the diaphragm, the diaphragm is displaced due to the pressure difference, and the pulse valve is opened. At this time, the compressed air is ejected from the air bag through the pulse valve through the nozzle hole (the gas ejected from the injection pipe is primary air). When the high-speed air flow passes through the venturi inducer, the surrounding air (called the secondary air) which is several times of the primary air enters the filter bag, causing the instantaneous positive pressure in the filter bag to achieve the purpose of ash cleaning. | The dust hopper is conducive to the discharge and collection of dust and the maintenance of the dust collector. The rotary valve can be configured to automatically and continuously transport the dust in the dust hopper to the conveying system or the collection container; Generally, the dust collecting bucket is equipped with two dust collecting bucket trucks, and the quick connection structure is adopted, which is closed and easy to open. The cleaning workers can easily open it and then pull it to the designated position to handle the dust, so that the environment is not polluted by the secondary flying caused by the shipping of other containers. | The single dust remover is controlled by a single machine, and the pulse controller is set as the timed automatic circulation ash cleaning. The combined dust remover is controlled by the pulse controller combination or PLC, and is set as the automatic circulation ash cleaning |

| Model of cartridge type dust collector | Number of filter cartridges | Filter area(m2) | Treatment air volume(m3/h) | Overall dimensions (mm) | Equipment resistance(Pa) | Air supply pressure for ash cleaning(MPa) |

|---|---|---|---|---|---|---|

| JT-LT-8 | 8 | 80 | 2400~4800 | 1008X2600X3100 | 800~1500 | 0.4~0.6 |

| JT-LT-16 | 16 | 160 | 4800~9600 | 2008X2600X3100 | ||

| JT-LT-24 | 24 | 240 | 7200~14400 | 3008X2600X3100 | ||

| JT-LT-32 | 32 | 320 | 9600~28800 | 4008X2600X3100 | ||

| JT-LT-40 | 40 | 400 | 12000~19200 | 5008X2600X3100 | ||

| JT-LT-48 | 48 | 480 | 14400~28800 | 6008X2600X3100 | ||

| JT-LT-56 | 56 | 560 | 16800~33600 | 7008X2600X3100 | ||

| JT-LT-64 | 64 | 640 | 19200~38400 | 8008X2600X3100 | ||

| JT-H3-12 | 12 | 120 | 3600~7200 | 1008X2600X3600 | ||

| JT-H3-24 | 24 | 240 | 7200~14400 | 2008X2600X3600 | ||

| JT-H3-36 | 36 | 360 | 10800~21600 | 3008X2600X3600 | ||

| JT-H3-48 | 48 | 480 | 14400~28800 | 4008X2600X3600 | ||

| JT-H3-60 | 60 | 600 | 18000~36000 | 5008X2600X3600 | ||

| JT-H3-72 | 72 | 720 | 21600~43200 | 6008X2600X3600 | ||

| JT-H3-84 | 84 | 840 | 25200~50400 | 7008X2600X3600 | ||

| JT-H3-96 | 96 | 960 | 28800~57600 | 8008X2600X3600 | ||

| JT-H4-16 | 16 | 160 | 4800~9600 | 1008X2600X4100 | ||

| JT-H4-32 | 32 | 320 | 9600~19200 | 2008X2600X4100 | ||

| JT-H4-48 | 48 | 480 | 14400~28800 | 3008X2600X4100 | ||

| JT-H4-64 | 64 | 640 | 19200~38400 | 4008X2600X4100 | ||

| JT-H4-80 | 80 | 800 | 24000~48000 | 5008X2600X4100 | ||

| JT-H4-96 | 96 | 960 | 28800~57600 | 6008X2600X4100 | ||

| JT-H4-112 | 112 | 1120 | 33600~67200 | 7008X2600X4100 | ||

| JT-H4-128 | 128 | 1280 | 38400~76800 | 8008X2600X4100 |

Note:

the equipment dimensions are for reference and can be designed and manufactured according to the customer's product dimensions.

If you want to customize it, you can click this text

1. It has double certificates of ISO9001 quality management system and environmental management system to protect the product quality

2. In 2014, it was listed as a high-tech environmental protection coating enterprise recognized by aerospace enterprises

3. National high-tech enterprise and safety production standardization certification company

1. Complete the technological innovation of "coating industrial robot", "coating waste gas treatment system", "environmental protection recycling abrasive recovery system" and "composite strong sand absorption base plate technology"

2. Obtained 8 national patents and possessed independent intellectual property rights

3. More than ten years of experience in the application and implementation of equipment (standard and non-standard) and production line customization projects, which is trustworthy

1. Not practicing fraud and sticking to quality is the first lifeline of the enterprise

2. The source equipment manufacturer has a warranty period of two years (excluding vulnerable and consumable parts), and the price is guaranteed on the basis of quality assurance

1. Have a professional trained construction team to complete the project with quality assurance

2. The after-sales department implements 7 * 24-hour telephone or online service

3. It has after-sales service stations in Beijing, Shandong and Zhejiang, and has a perfect after-sales system with high troubleshooting efficiency