The bag type dust collector is a process of filtering dust particles by using organic fiber or inorganic fiber filter cloth based on the pulse filtration principle. It belongs to a dry type dust removal device and is suitable for collecting fine, dry and non fibrous dust. The bag structure increases the cotton area of the air inlet by 3-4 times. The use of this filtering form can reduce the wind resistance, increase the dust capacity and reduce the number of replacement, so as to save energy and reduce costs.

The nine way cloth bag filter is a bag filter made of vnf "all-louders" series synthetic fiber filter material product vnf-290 (G3) of the Netherlands "Filtrair" company, with a filtration accuracy of 0.2 μ m. The filtration efficiency is as high as 99.5%, and the air leakage rate is less than 0.1%. It has the advantages of high purification efficiency, large gas processing capacity, simple operation, stable performance, long filter bag life, good ash removal efficiency, and small maintenance volume. It has been applied in China Shenzhou aircraft Co., Ltd., Beijing Lantian glass factory, Hebei runkun Co., Ltd. and other companies. The source manufacturers offer quotations with quality and quantity guaranteed.

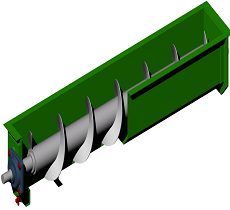

旋风+布袋.jpg

High filtration accuracy: the box is airtight design, excellent sealing material, and strong sealing performance. Kerosene is used for leak detection in the manufacturing process, and the filtration accuracy is 0.2 μ m. Air leakage rate & lt; 0.1%, ultra clean emission

High dust removal efficiency: the collection efficiency is as high as 99.5%, and the dust concentration in the outlet gas is within 20 mg / m3. It has a high classification efficiency for fine dust with sub micron particle size

Convenient installation and maintenance: simple and compact structure, easy installation, flexible use, convenient maintenance, easy to recover dry materials, no sludge treatment

Good ash cleaning effect: adopt the technology of pulse blowing with air stop in each room to completely clean the ash once, prolong the ash cleaning cycle, reduce the consumption of ash cleaning air, reduce the fatigue degree of filter bag and pulse valve, and improve the service life of filter bag and valve piece

Strong economy: compared with the cartridge type dust collector, its use, operation and maintenance costs are lower

High temperature resistance: when glass fiber, polytetrafluoroethylene, P84 and other high temperature resistant filter materials are used, they can operate under high temperature conditions above 200 ℃

The bag type dust collector is widely used in the flue gas treatment and dust removal systems of mines, chemical industry, coal, non-metallic mineral powder processing, hardware, building materials, chemical industry, casting, plastics, metallurgy, electric power, mechanical processing, auto parts processing plants, iron smelting plants, steel-making plants, ferroalloy plants, fire-resistant plants, power plants, embryo drying, mixing, polishing, etc.

|  |  |  |  | ||

| working principle | Ash removal principle |

The high dust removal efficiency of the bag filter is inseparable from its dust removal mechanism. When the dusty gas enters the ash hopper through the deflector through the air inlet pipe at the lower part of the dust collector, due to the impact of the deflector and the reduction of the gas velocity, the coarse dust will fall into the ash hopper, and the remaining fine dust will enter the filter bag room with the gas. Due to the inertia, diffusion, barrier, hooking, static electricity and other effects of the filter material fiber and fabric, the dust will be trapped in the filter bag, and the purified gas will escape out of the bag and be discharged through the exhaust pipe. The accumulated dust on the filter bag is removed by gas back washing method. The removed dust is discharged to the ash hopper and discharged to the ash conveying device through the double-layer ash unloading valve. The accumulated dust on the filter bag can also be removed by spraying pulse air flow, so as to achieve the purpose of ash removal. The removed dust is discharged by the ash discharge device. | The top of the outlet of each row of filter bags is equipped with a blowing pipe, and the lower side of the blowing pipe is directly opposite to the filter bag. A pulse valve is set on each blowing pipe and connected with the compressed air bag. During ash cleaning, the electromagnetic valve opens the pulse valve, and the compressed air is sprayed by the ash cleaning control device (differential pressure or timing, manual control) to open the electromagnetic pulse blowing according to the set procedure, The compressed gas passes through each pulse valve in sequence in a very short time and induces the air several times as much as the injected air into the filter bag through the nozzle on the injection pipe to form an air wave, which causes the filter bag to undergo rapid expansion and impact vibration from the bag mouth to the bottom, resulting in a strong ash cleaning effect. The purpose of ash cleaning can be achieved by blowing once. Therefore, the ash cleaning cycle is prolonged, the energy consumption for ash cleaning is reduced, and the air consumption can be greatly reduced. At the same time, The fatigue degree of the filter bag and the pulse valve is also correspondingly reduced, thereby doubling the service life of the filter bag and the valve plate. |

|

|

The box shell of the bag type dust collector is made of steel plate welding type, light combined type and external insulation type, which can flexibly meet different operating conditions; The box body is mainly used to fix the dust removal framework, filter bag and air circuit elements, and is made into a fully enclosed form. The top is provided with a manhole access door, which can easily install and replace the bag cage and dust removal filter bag; The boxes of different specifications can be customized according to the needs. The box is divided into several chambers, separated by partitions, which are airtight to each other and realize off-line ash removal; Each room is equipped with a poppet valve to switch the filtered air flow; The upper box is designed with a certain slope, which is conducive to the smooth drainage of rainwater; The middle box is made of steel plate with thickness of 5mm, and the surface is painted with rust prevention, firmness and durability. |  |

|  |  |  |  |

| Bag room | Filter bag | Ash removal system | Ash bucket | Air inlet and outlet |

At the lower part of the box, it is mainly used to accommodate the bag cage and the dust removal cloth bag to form a filter space. According to the requirements, it is divided into several chambers according to different specifications and separated by partitions to prevent mutual interference between the chambers during the ash removal and form a certain settlement space. | It can be divided into flat bags (trapezoidal and flat) and circular bags (cylindrical). The bag structure can increase the filter area of the air inlet, which is 3-5 times larger than the conventional plate filter; The glass fiber needle felt material has the advantages of high filtration efficiency, easy dust peeling, long service life, etc. the vertical installation makes the pulse ash cleaning easier, and avoids the "bridging" phenomenon of ash cleaning when the filter bag is installed horizontally | The pulse air flow is used for ash blowing and cleaning. The technology of pulse blowing and cleaning by stopping air in different rooms overcomes the shortcomings of conventional pulse dust collector and reverse blowing dust collector in different rooms. It has good ash cleaning capacity, low emission concentration, low air leakage rate, low energy consumption, less steel consumption, less land occupation, stable operation and good economic benefits. | The ash hopper is arranged at the lower part of the bag chamber, which has the function of collecting dust and serving as the air inlet header. The ash hopper has a large volume, which can reduce the air flow speed. In addition, the change of the air flow direction makes the coarse dust particles separated here. The lower part of the ash hopper is provided with conveying equipment such as screw conveyor or air chute. The outlet is also provided with air lock equipment such as rotary unloader or flap valve, which can continuously discharge the ash. | The air inlet and outlet can be divided into two types. One is cylindrical, which is directly welded on the side plate of the ash hopper. The air outlet is arranged at the lower part of the box and the side of the bag chamber, and is connected with the inside of the box through the lifting valve plate hole; The other is that the air inlet and outlet are integrated and arranged on the side of the bag chamber, between the box and the ash hopper. The middle is separated into two airtight parts, namely, the air inlet and the air outlet. Although the structure is larger, the air flow distribution is uniform, and the pre dedusting effect in the ash hopper is good. It is suitable for the occasions with large dust concentration in the flue gas. |

electric controlThe electrical control system of the bag type dust collector adopts PLC controllers with differential pressure, timing and manual options to comprehensively control and detect the ash cleaning pulse valve, ash unloading device, bypass valve, ash hopper electric heating, material level, etc. of the dust collector. |  |

| Model of bag type dust collector | JT-BD36 | JT-BD40 | JT-BD50 | JT-BD60 | JT-BD80 |

|---|---|---|---|---|---|

| Number of cloth bags (PCs.) | 36 | 48 | 60 | 72 | 96 |

| Bag specification (mm) | Φ150×1500 | Φ150×1500 | Φ150×1500 | Φ150×1500 | Φ150×1500 |

| filtration velocity(m/min) | 1-2.5 | 1-2.5 | 1-2.5 | 1-2.5 | 1-2.5 |

| Treatment air volume(m³/h) | 1800 | 2400 | 3000 | 5000 | 6000 |

Note:

the equipment dimensions are for reference and can be designed and manufactured according to the customer's product dimensions.

If you want to customize it, you can click this text

1. It has double certificates of ISO9001 quality management system and environmental management system to protect the product quality

2. In 2014, it was listed as a high-tech environmental protection coating enterprise recognized by aerospace enterprises

3. National high-tech enterprise and safety production standardization certification company

1. Complete the technological innovation of "coating industrial robot", "coating waste gas treatment system", "environmental protection recycling abrasive recovery system" and "composite strong sand absorption base plate technology"

2. Obtained 8 national patents and possessed independent intellectual property rights

3. More than ten years of experience in the application and implementation of equipment (standard and non-standard) and production line customization projects, which is trustworthy

1. Not practicing fraud and sticking to quality is the first lifeline of the enterprise

2. The source equipment manufacturer has a warranty period of two years (excluding vulnerable and consumable parts), and the price is guaranteed on the basis of quality assurance

1. Have a professional trained construction team to complete the project with quality assurance

2. The after-sales department implements 7 * 24-hour telephone or online service

3. It has after-sales service stations in Beijing, Shandong and Zhejiang, and has a perfect after-sales system with high troubleshooting efficiency