The water spinning spray booth captures the spray mist through liquid water, prevents the diffusion of the spray mist by means of gas laminar flow suppression, and filters the spray mist through hydraulic spinning pipe. The filtration efficiency can reach 98% - 99.5%. It is a technically complete spray booth. Jiutong water spray booth has the advantages of flexible and convenient installation, safe and reliable operation, no waste water discharge, simple operation and maintenance, energy saving and environmental protection, and dust removal efficiency of more than 98%. It has been successfully applied in Qingdao CIMC refrigerator manufacturing, Baotou Guodian power, Langfang Zhongchen petroleum equipment, Liaoning Huarong heavy industry machinery and other enterprises, and has won unanimous praise from customers.

水旋喷漆房2.JPG

The plane of the spray booth can be large or small. It is suitable for spraying large, medium or super large workpieces with high output and can realize continuous batch production

The paint capacity is large, so it does not need to be maintained frequently or infrequently as in the dry-type paint booth, nor does it have a great impact on the air supply and exhaust effect

Compared with the non pump water curtain, this equipment has a large water consumption and a complex foundation, but the consumption is smaller than that of the venturi spray booth

Simple structure, no clogging problem, small maintenance, high paint mist treatment efficiency, up to 99.5%

The waste gas treated by water spinner paint mist meets the environmental protection technical requirements of industrial three wastes emission, and the waste gas treatment is easier than that of dry spray booth

No waste water is discharged, and the equipment structure has strong adaptability to the water quality. The water containing a large amount of paint residues will not be blocked in the circulation, nor will the purification effect of paint mist be affected by the presence of paint residues in the water

The water spin spray booth is widely used in household appliances, bicycles, domestic and commercial steel furniture, automobile, motorcycle parts and surface spraying, instrument and meter housings, electrical cabinets, agricultural machinery, sports equipment, and others.

|  |  |  |  | ||

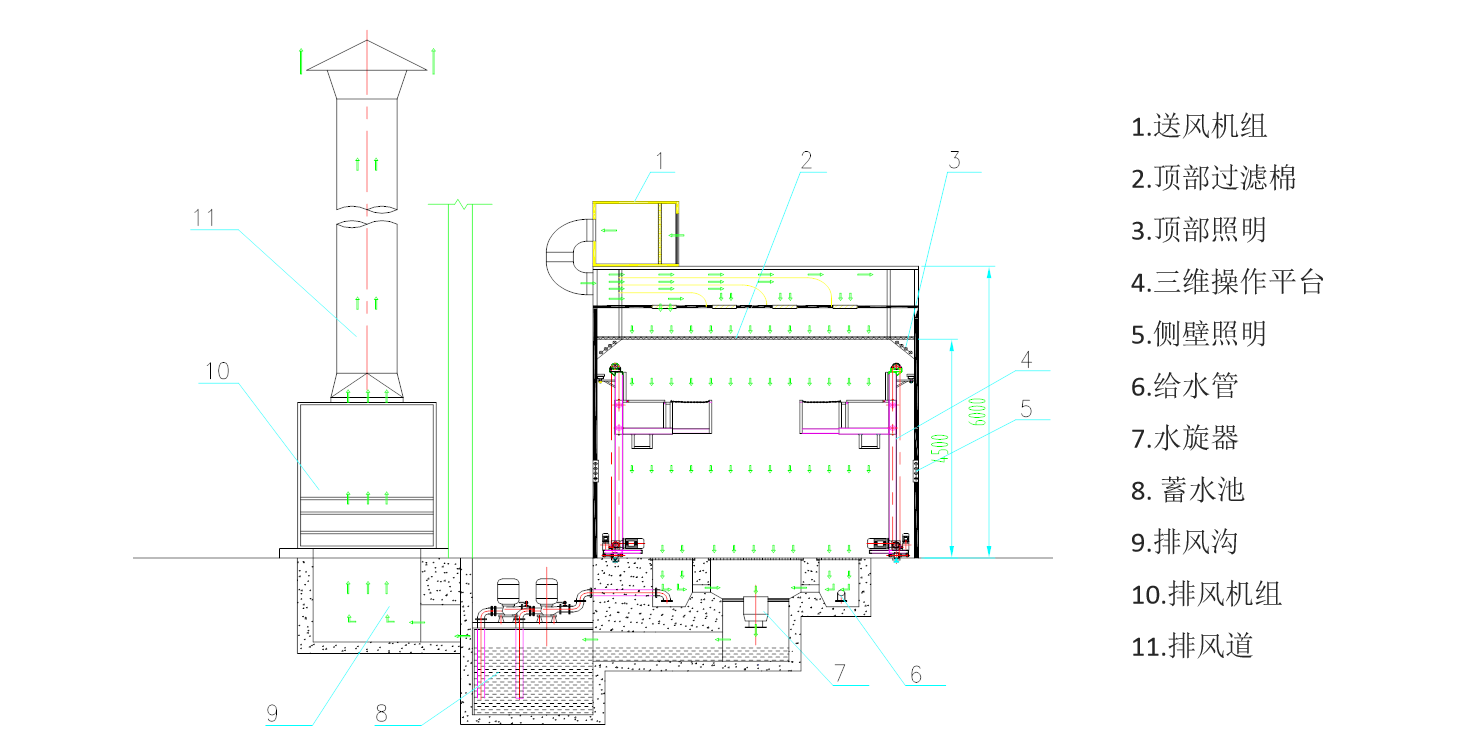

In the working state of the water spray booth, the air conditioner blower, exhaust fan and circulating pump are started. The outdoor fresh air is purified by the air inlet and sent to the static chamber by the air conditioner blower. The filter top cotton at the bottom of the static chamber equalizes the air flow and blocks the solid dust. The clean air enters the room in a laminar flow mode, forming an orderly air flow around the work, so that the residual paint mist of the paint spray does not disperse around, so as to protect the labor safety of the operators and workers. Under the action of the air flow, the air flow passes through the water spinner in an orderly manner. The water spinner atomizes the water into fine water droplets, fully washes the air containing the paint mist, separates the paint mist from the air, and achieves the purification effect. The treatment of the paint mist is to use a water spinner to atomize the water and wash the air to purify the paint mist. The structure is simple, there is no clogging problem, the maintenance is small, and the paint mist treatment efficiency is high, up to 99.5%. The waste gas treated by the water spinner paint mist is discharged into the atmosphere by the chimney under the action of the exhaust fan, so as to ensure that the environmental protection technical requirements for industrial three wastes emission are met.

|  |  |  |  |

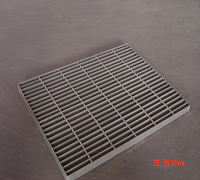

| Main material of chamber | Air distribution room | Electric liftgate | Working status warning lamp | foot level grill |

The framework column of the water spin paint booth adopts the framework. The column and the beam are both made of profile steel, and the surface is subject to anti-corrosion treatment. The wall plate adopts 75mm rock wool sandwich plate, and the inside and outside are 0.5mm galvanized color steel plates. U-shaped plug connection is adopted between the wall plates, and U-shaped groove connection is adopted between the wall plates and the framework. The whole splicing joint is coated with sealant, and the strength, stability, thermal insulation, sealing, impact resistance, durability and noise meet the requirements of national or industrial standards. | It is composed of a dynamic pressure chamber (i.e. an air supply chamber) and a static pressure chamber. The height of the dynamic pressure chamber is about 1000mm. It adopts the all steel welded structure of the profiled steel skeleton box plate. The air is evenly distributed into the static pressure chamber through the distributor and the non-woven fabric bag filter; The static pressure chamber is set at the lower part of the dynamic pressure chamber, with a height of about 1200 mm, so that the fresh air can flow evenly to the operation room after preliminary filtration. The filter material of the distribution layer of the static pressure chamber is supported by a C-shaped top net, and a movable pressure frame is set to prevent the distribution layer from floating. | Customizable, such as electric opposite door, manual opposite door, flexible door, etc. customers can choose by themselves; If there are small workpieces, it is recommended to use flexible doors. The flexible doors of small workpieces are closed and the large workpieces are opened, which can save energy and improve the working environment; Lighting glass is installed on both sides of the room, and 5mm thick tempered glass is used to increase the indoor light intensity. | A flashing warning light is set on the top of the front end of the gate to remind the staff of the working state in the room. When the green light is on, the spray booth is in normal working condition; It is in fault state when the red light is on; When no light is on, it is in the stop use state. | A pit sump is set at the bottom of the chamber, and a grid plate is laid on the top of the chamber, which is hot-dip galvanized after processing, so as to avoid the waste newspaper and waste tape generated by the scribing and pasting of the decorative tape during the painting of the workpiece from entering the underground structure pool. Grid hole size ≤ 40 × 40mm, 3 × 40mm flat steel, the floor is made of block assembly structure, which is convenient for disassembly and assembly. |

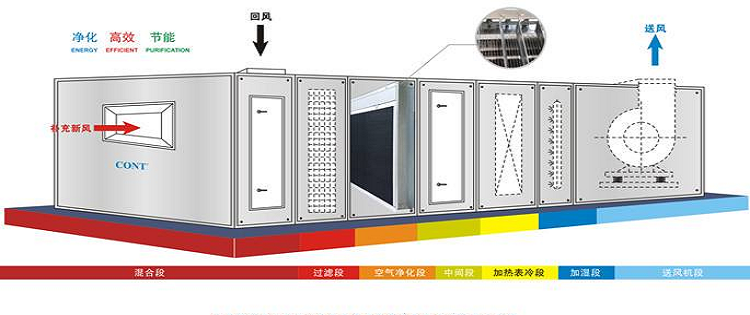

The controlled wind speed of the water spinning spray booth must comply with the safety technical regulations for spray booth in gb14444-2006 safety regulations for painting operations & gt; Required control wind speed. The principle of micro positive pressure shall be considered for the air supply volume of the spray booth, that is, the exhaust volume is slightly less than 3-5% of the air supply volume, so that the external dust will not enter the operation area through the door seam of the room. The modular design concept organically combines the air supply and heating systems into a set of modular systems, and skillfully organizes the air flow inside. The framework of the module system is welded by industrial profiles, and the surface is paved δ 100mm rock wool color steel sandwich panel, and access doors are set in each functional area. |  |

|  |  |  |

| Air inlet section | Filter section | Fan section | Heating section |

The air inlet is installed with metal mesh to prevent birds and sundries from being sucked in. The air inlet is arranged indoors and the air outlet is arranged at high altitude to ensure that the exhaust gas will not be sucked in again; An air volume regulating valve is provided to regulate the air inlet volume to ensure the matching with the exhaust volume; The air valve conversion section is to realize the conversion of spraying and drying paint. It is composed of an air valve and an automatic air valve controller. The automatic air valve controller is a Swiss bellmo product with sensitive response and accurate action. | The fan case is made of profile as wall plate, composite metal frame structure, and equipped with one access door. The air box is equipped with primary and medium effect filters. The primary effect filter is a bag type non-woven fabric filter with aluminum alloy frame, and the type is four bag type. The synthetic fiber filter material vnf-290 of vnf "all-louders" series of the Netherlands "Filtrair" company is adopted, with a filtration accuracy of G3 and a filtration efficiency of ≥ 80%. Medium efficiency filtration adopts 5-bag aluminum frame non-woven fabric filter, with filtration accuracy of F5 and filtration efficiency ≥ 85%. | The fan adopts double suction bkkf explosion-proof centrifugal fan, which has the characteristics of good performance, high efficiency, beautiful appearance, compact structure, stable operation, and convenient installation and maintenance. The forced draft fan base is welded into a frame with channel steel and angle steel industrial profiles to bear the weight and vibration of one forced draft fan; Air supply pipes are all made of δ 1.2mm high-quality galvanized steel plate undercut production, without welding, to ensure that the pipeline is formed without deformation; A damping or elastic reducer is installed at the bottom of the fan. At the same time, we have designed a fan noise reduction room to ensure that the system noise is controlled below 75dBA | In order to ensure the adhesion between the paint film and the workpiece substrate in winter, it is generally required that the ambient temperature should be ≥ 15 ゜ C. the added heating device ensures the spraying effect of the operation at low temperature in winter and is integrated into the air supply system; According to the requirements of heating power value in winter, btg28p two-stage fire gas burner of Italian "Baltur" company is selected as the burner, which is safe and energy-saving |

| The selection of the exhaust fan in the water spray painting room is mainly determined by the two parameters of the fan air volume and the fan head. The frame is welded with channel steel and angle steel industrial profiles, and the exhaust pipe is made of δ 1.2mm high-quality galvanized steel plate undercut production, without welding, to ensure that the pipeline is formed without deformation; A damping or elastic reducer is installed at the bottom of the fan, and a fan noise reduction room is designed to ensure that the system noise is controlled below 75dBA; The size of the exhaust chimney is determined by the air flow velocity and the concentration of harmful substances discharged. The wind resistant structure is used for reinforcement in the installation. |

It is composed of high-pressure airless paint pump, pneumatic mixer, paint filter and pipeline. It is installed in the paint pump room (paint supply room). The paint pump system is connected to the paint booth by pipeline

| Paint supply room One (5.5m) is installed under the platform of the air supply system × 2m × 3m(L × W × H) Paint supply room. Equipped with exhaust fan, the exhaust volume shall not be less than 10 times / min, and explosion-proof exhaust fan and lighting shall be adopted. Ground wires shall be buried in the paint supply room to prevent fire caused by static electricity; In order to facilitate the painting operation, compressed air quick connectors are set on both sides of the paint booth |

| Spray gun American Graco manual high-pressure airless spray gun is adopted, with ergonomic design and strong comfort; Elliptical insulated handle, high safety; The structure design is compact and reasonable, with mobile hose, flexible operation even in narrow space, and high spraying quality; The spray gun filter is easy to take out and easy to repair, reducing the maintenance time due to nozzle blockage. |

| Robot painting With the rising labor cost and the gradual disappearance of the population dividend, it has become an inevitable trend for robots to replace people. The robot is used to replace the spray painting workers for spray painting, which can avoid the heavy labor of the operators in the harsh working environment, and can ensure the stable surface quality of the workpiece and high production efficiency. |

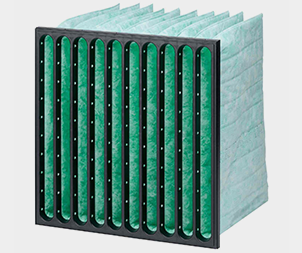

Grade 2-3 filtration is adopted: primary 1-2 filtration and sub high efficiency filtration (top filtration) of air inlet, which is composed of air inlet filter, top filter material, top cotton support net, connecting plate, etc; The sub high efficiency filter material is set at the bottom of the static chamber and supported by the top cotton support net. The top cotton support net is of high-quality C-shaped steel structure. After special rust prevention treatment, it has good rigidity, no corrosion and easy to replace the top cotton;

| Primary filter material |  | Sub high efficiency filter material |

The synthetic fiber filter material product vnf-290 (G3) and the bag filter of the filter section of the air supply system can increase the cotton area of the air inlet by 3-4 times with the cloth bag structure. The adoption of this filter form can reduce the wind resistance, increase the dust capacity and reduce the replacement times | The Dutch "arresters" synthetic fiber filter material cc-600g (F5) is selected as the sub high efficiency filter material, which can filter out all particles that can damage the paint quality, and the dust content is 100% removed to ensure that the air flow passing through the paint booth is evenly diffused and forms a laminar flow state, which conforms to the fire classification standards of European din53438-f1 and American ul900-class1. |

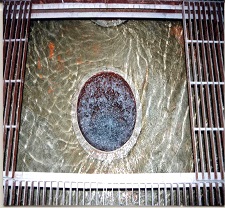

| The paint mist treatment in the water spinning spray booth is to use the water spinning treatment system installed under the floor grid to atomize the water and then wash and purify the paint mist. The paint mist treatment efficiency can reach 99.5%. The air sent from the top of the chamber flows vertically downward along the whole section after passing through the dynamic pressure chamber air equalizing filter and passing through the sub high efficiency filter layer of the static pressure chamber. Under the action of the air extraction system, the sprayed paint mist is coated. The air and water containing the paint mist enter the water spinner at the same time. The water is atomized into fine water droplets in the water spinner, and the paint mist in the air is fully washed and adhered to separate the paint mist from the air, and then discharged after purification, At the same time, the painters can operate in the fresh air to avoid the pollution of the working environment. It is composed of circulating water tank, circulating water pump, water injection pipe, washing water tank, water spinner, sump, sewage pump, air-water separator, paint residue fishing device, etc. |

|  |  |  |  |

| water circulating pump | Water spinner | Gas water separator | Sewage pump | Paint residue fishing device |

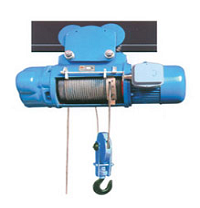

The circulating water pump lifts the water in the circulating water tank and injects it into the water injection pipe. The cantilever submerged pump is selected as the circulating water pump. Compared with the ordinary submerged pump, it has the advantages of small volume, high efficiency, good energy saving effect and reliable operation. It is suitable for conveying corrosive media without solid particles and abrasives. | The water spinner is composed of a circular power tube and an impact plate. The outlet of the power pipe is a tapered pipe orifice, and the air flow rate at the constriction orifice is 20-25m / s. The impact plate is a round thick plate. The plate surface is processed into several rhombus shapes or drilled with several holes to increase the disturbance of impact reflection. The water spinner is evenly arranged along the center line of the washing tank, with a spacing of 1000mm. The overflow of the water spinner is 70-100 mm higher than the bottom of the washing tank. Keep the washing tank at a certain level. | The baffle type air-water separation device is used to prevent some water droplets from cleaning the paint mist from being sucked into the ventilation duct and prevent the paint from adhering to the impeller of the exhaust fan and affecting the operation of the fan. Set 2-4 baffles. When the water mist collides between the baffles, the water mist condenses into large water droplets and flows down from the baffles to separate from the air. For water baffle δ 2mm thick stainless steel plate. For the convenience of cleaning, paint peeling agent shall be applied on the board surface or paper shall be pasted with butter to make the waste paint adhered to it easy to peel off. | If the water in the circulating water tank is used for a long time and has serious pollution, it needs to be regularly discharged to the centralized sewage tank of the factory for treatment. The sewage pump is designed with a special channel impeller with a wide flow channel and a reasonable pump body design, so that the pump body and the impeller can be optimally matched. The solid particles are not blocked, the ribbon fibers are not entangled, and the submersible work does not require a bottom valve. It is most suitable for discharging sewage | A circular chain electric hoist CD1 is set above the circulating water tank for the salvage treatment of paint slag. The rigid frame of the electric hoist and the steel platform of the air supply system are integrated to reduce the system cost. |

During painting, the exhaust gas shall be treated to make the treated exhaust gas meet the integrated emission standard of air pollutants (gb16297-195). There are two commonly used treatment methods in our company's water spinning spray booth: activated carbon system + RCO catalytic combustion and molecular sieve zeolite runner adsorption + catalytic combustion.

|  |

Activated carbon adsorption + RCO catalytic combustion The organic waste gas can be adsorbed by using the adsorption characteristics of activated carbon micropores, and the waste gas with low concentration, low temperature and hydrocarbon can be treated. The solvent can be recovered and reused, and the purification efficiency is as high as 90-95%. Activated carbon is a non-polar adsorbent with hydrophobic and organophilic properties. It can absorb most organic gases, such as benzene, aldehydes and ketones, alcohols, hydrocarbons, etc., as well as odor substances. After the adsorption is saturated, it can be desorbed and regenerated by hot air and put into use again | Molecular sieve zeolite runner adsorption + catalytic combustion The zeolite runner concentration area can be divided into treatment area, regeneration area and cooling area. After collection and pretreatment, VOC organic waste gas enters the zeolite molecular sieve runner system. Through the continuous process of adsorption desorption concentration of zeolite molecular sieve runner, large air volume and low concentration organic waste gas is concentrated into small air volume and high concentration waste gas, and then enters the regenerative oxidation furnace for combustion purification, And effectively utilize the surplus heat released by the combustion of organic matter. |

|  |  |  |

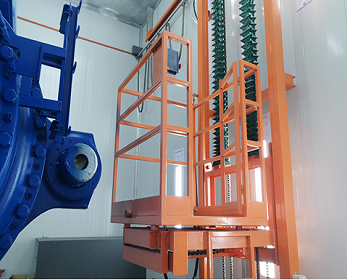

Combustible gas detection and alarm device to ensure safety | The lamp is explosion-proof, durable and comfortable | The 3D operation platform is efficient and flexible | The electric control system is well-known and reliable |

| Serial number | name | unit | numerical value | parameter |

|---|---|---|---|---|

| 1 | Paint booth type | Water spin closed spray booth | ||

| 2 | Equipment size | mm | 13000*7000*5000mm | |

| 3 | Gate size | mm | 6000*4000mm | |

| 4 | wind speed | m/s | ≥0.35 | No load |

| 5 | Air supply volume | m³/h | 115000 | Outward wind speed |

| 6 | working temperature | ℃ | ≥15 | Steam heating |

| 7 | Exhaust air volume | m³/h | 10800m³/h | Explosion proof motor |

| 8 | Fan power | KW | 9.0*6+22*3=120 | |

| 9 | Lighting power | KW | 3.8 | Explosion proof lamp |

Note: the equipment dimensions are for reference and can be designed and manufactured according to the customer's product dimensions.

If you want to customize it, you can click this text

1. It has double certificates of ISO9001 quality management system and environmental management system to protect the product quality

2. In 2014, it was listed as a high-tech environmental protection coating enterprise recognized by aerospace enterprises

3. National high-tech enterprise and safety production standardization certification company

1. Complete the technological innovation of "coating industrial robot", "coating waste gas treatment system", "environmental protection recycling abrasive recovery system" and "composite strong sand absorption base plate technology"

2. Obtained 8 national patents and possessed independent intellectual property rights

3. More than ten years of experience in the application and implementation of equipment (standard and non-standard) and production line customization projects, which is trustworthy

1. Not practicing fraud and sticking to quality is the first lifeline of the enterprise

2. The source equipment manufacturer has a warranty period of two years (excluding vulnerable and consumable parts), and the price is guaranteed on the basis of quality assurance

1. Have a professional trained construction team to complete the project with quality assurance

2. The after-sales department implements 7 * 24-hour telephone or online service

3. It has after-sales service stations in Beijing, Shandong and Zhejiang, and has a perfect after-sales system with high troubleshooting efficiency