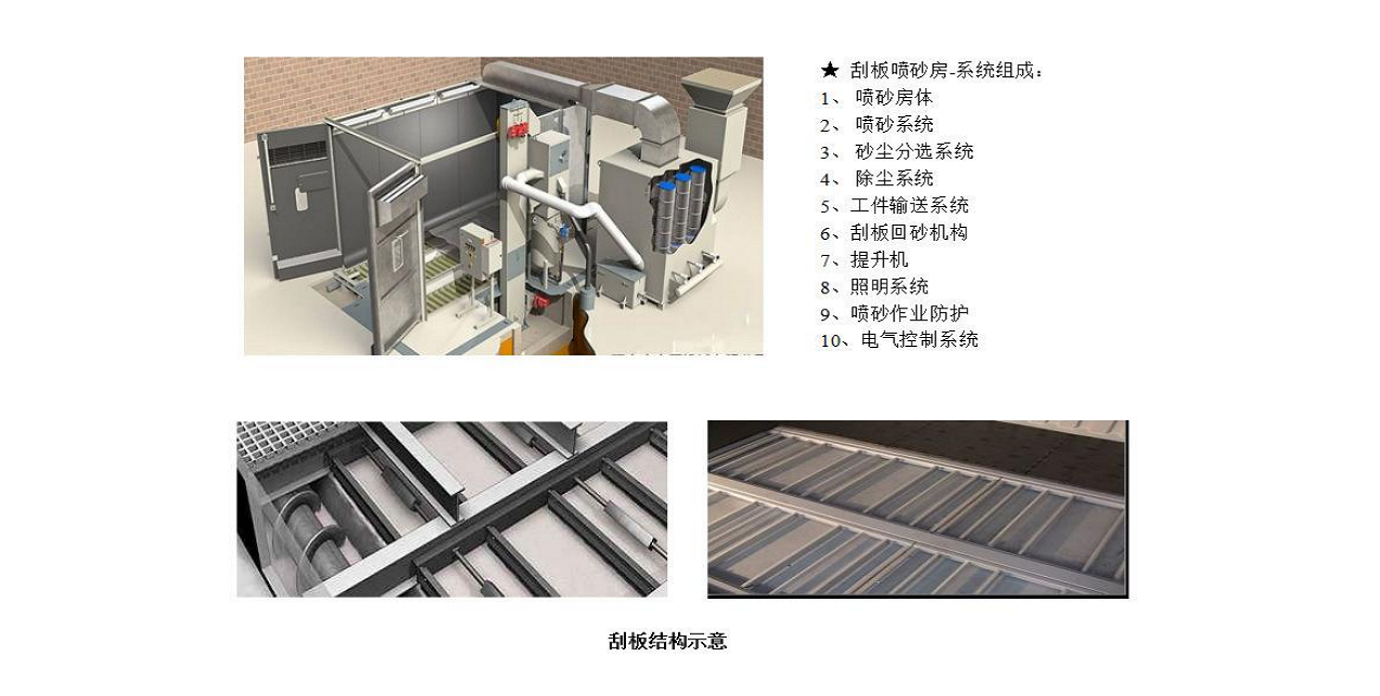

The scraper vacuum recovery sandblasting room is a kind of mechanical recovery + pneumatic recovery sandblasting room. The scraper + vacuum recovery equipment and separator are used to realize the transportation and recycling of sand. The scraper design can reduce the equipment foundation (generally 500-900mm) to the greatest extent, and it can also build a foundation on the ground without digging a pit; Its vacuum pipeline replaces mechanical transmission equipment to reduce the failure rate; The vacuum suction reaches more than 10000 kPa, and the suction is large. Even if the sand blasting room is more than 50 meters, there will be no sand blockage.

There are many kinds of sandblasting applicable, and there are no limitations on the processing of workpieces. It is suitable for sandblasting of all kinds of large and medium-sized parts (with large surface impurities and heavy quality), and meets the requirements of removing rust, oxide skin, burrs, electroplating and pretreatment before coating.

图片17.png

1. Shallower Foundation: Vacuum scraper design, which is shallower than other machinery and wind recovery Foundation (generally 500-900mm), can also build a foundation on the ground without digging a pit, and the equipment cost is lowe

2. High stability: the vacuum pipe replaces the mechanical transmission equipment, and the mechanical failure rate is low; The vacuum pump has large suction, no sand plugging, high stability and simple maintenance

3. Excellent structural design: the friction between the scraper and the sand return floor is small, the abrasive damage rate is small, the scraper structure is protected, and the high wear-resistant scraper has a long service life

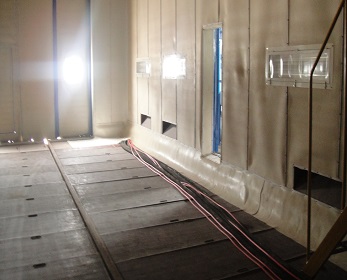

4. Good working conditions: the visibility in the room is high, the dust volume is low, the working room is clean, and the abrasive noise of the sand return system is very low, which is conducive to the physical and mental health of workers

5. High dust removal efficiency: cartridge filter is adopted, which has high efficiency, large filtering area, low filtering wind speed, low resistance and long service life, so as to ensure that it meets the national emission standards

6. Low energy consumption: the scraper of the abrasive system recovery system adopts cylinder motion, and the vacuum sand return adopts vacuum pump operation, and the separation device adopted does not need energy consumption

The scraper vacuum recycling sandblasting room is suitable for all kinds of sandblasting, shot blasting and sanding operations, such as engineering machinery, bridge steel structure, heavy machinery, containers, rolling stock, aerospace, petroleum and petrochemical, electric power, weapons and other industries.

|  |  |  |  |

| Working principle of sand blasting system | Working principle of sand recovery system |

The sand is stored in the sandblasting tank of the sandblasting host. When sandblasting is carried out, the combined valve on the sandblasting tank acts to jack up the sand seal bracket on the sandblasting tank and pressurize the sandblasting tank; At the same time, the sand valve and boost valve under the sandblasting tank are opened; As the sand blasting tank is pressurized, the sand material is forcibly pressed out from the sand inlet of the sand valve to the sand outlet, and the sand material at the sand outlet of the sand valve is accelerated by boosting the air flow; The mixed flow of the accelerated sand flow passes through the sand blasting pipe to the high-speed sand blasting gun and further accelerates the sand in the high-speed sand blasting gun (boosting the air flow to accelerate to supersonic speed); The accelerated sand is sprayed to the surface of the workpiece to be treated at a high speed, so as to achieve the purpose of surface cleaning and strengthening of sand blasting operation. | The abrasive in the scraper vacuum recovery sand blasting room directly falls to the scraper machine through the grid plate. The scraper machine transmits the indoor abrasive and dust mixture to the honeycomb funnel at the end and enters the vacuum sand return equipment. The vacuum device is sucked through the abrasive recovery horizontal pipe and riser of the vacuum recovery equipment, and then sent to the abrasive separation system to separate the abrasive, dust and foreign matters through the abrasive separator, The useful sand enters the sand blasting tank for continuous recycling. The dust and foreign matters enter the dust removal system with the air flow and are discharged into the atmosphere after being treated by the dust removal system. The dust and foreign matters are stored in the dust cylinder and cleaned regularly. |

The design can be customized according to the size, size and transportation mode of sandblasting workpiece. The scraper vacuum recovery sandblasting room is made of 75mm color steel sandwich board, which reduces the sandblasting noise to below 500Hz, greatly improves the noise environment, has good corrosion resistance, weather resistance and beautiful appearance. A manual folding door is set on one side of the room for the entry and exit of workpieces. An observation window is left on the door. The glass of the observation window is equipped with an anti sandblasting impact device. The surrounding seal of the door adopts a special sealing strip for the door, which has good sealing performance and is solid and reliable; Sandblasting hand holes (a pair) and sandblasting windows are installed in the middle of both sides of the room (the location and quantity can be reasonably installed according to the actual needs). The operator can operate the spray gun outdoors. |  |

| It is mainly composed of sand blasting host, sand valve, stop valve, rotary charging valve, high-speed spray gun, etc; The sandblasting host adopts nine way jt-11-900y/1500y high-efficiency continuous sandblasting machine (large capacity, double bin structure), adopts the pressure maintaining working principle, and can carry out sandblasting operation with 2-4 sand control valves and 2-4 high-speed spray guns at the same time. The sand loading capacity is large, and a tank can hold about 5-10 tons of steel sand; The sandblasting tank is designed and manufactured in accordance with ASME standards. The sandblasting tank is designed and manufactured in accordance with ASME standards, and has passed the full inspection by the local boiler and Pressure Vessel Inspection Institute, meeting the requirements of relevant national standards. |

|  |  |  |  |

| Sand valve | Rotary charging valve | Globe valve | sand blasting gun | robot |

The main function of the sand valve is to control the opening and closing of the sand, and infinitely adjust the amount of sand during sand blasting. The nine way adopts the pneumatic control pipe clamp sand control valve of clemco company in the United States, adopts the jacket structure, and the driving part is a diaphragm cylinder, which has the advantages of stable and reliable performance, almost no maintenance, large sand production, sensitive control, safety and reliability, long service life (more than 3000 hours). Customers can also choose Thomson or domestic sand valves | The function of the rotary charging valve is to control the amount of sand added to the sandblasting tank. It is installed on the top of the sandblasting host. The sandblasting tank is opaque, which makes it difficult for the operator to distinguish the amount of sand added in the sandblasting tank. Therefore, a material level sensor is installed on the sandblasting tank. When the sand in the sandblasting tank reaches the set value, the rotary charging valve on the sandblasting tank will automatically close, which is intelligent and convenient | The main function of the stop valve is to close the stop valve when the sand valve is replaced or repaired, so that it is not necessary to discharge all the sand material when replacing and repairing the sand valve, saving time and effort. The valve is the latest development and is free of maintenance and repair for life | The sandblasting gun adopts a high-speed sandblasting gun designed by nine links. The venturi shaped nozzle is divided into contraction section, straight section and expansion section. Its material is made of boron carbide, and its service life is long. A high-speed gun can be used for 800-1000 hours; Compared with the ordinary spray gun, the venturi spray gun has faster sand blasting speed, 50% higher working efficiency, and the working efficiency can reach 35m2/h, with small recoil force, high efficiency and labor saving. | Customers can choose the sandblasting robot to complete the sandblasting operation, which has the advantages of energy conservation, environmental protection, high efficiency, high quality, intelligence, automation, high safety, wide application range and so on. It is the general trend to use the sandblasting robot for operation. Sandblasting robots include gantry type, side wall type and inner wall type, which can be divided into four to thirteen axis sandblasting robots according to the number of mechanical axes. Customers can customize and purchase according to the different processing requirements of workpieces. |

Scraper vacuum recovery sandblasting room the abrasive recovery system is composed of scraper type automatic full sand return floor, vacuum recovery equipment and abrasive vibration screening machine.

| Plate type automatic full sand return floorScraper type sand return floor is only used for 0.5m each ³/ Min pneumatic scraper drive mechanism; It can be designed as a pit free structure, the floor is directly placed on the cement floor, and the height of the surrounding maintenance structure is 400-600mm; The low-power motor completes the efficient automatic recovery of large-area floor abrasives. The automatic sand return floor and the abrasive vacuum lifting and circulating screening system can operate intermittently according to needs, so as to further reduce energy consumption and greatly reduce the use cost; The design and material selection of the polyurethane scraper with no wear and high wear resistance during floor recycling ensure the super long service life of the scraper system, and the maintenance is simple, rapid, convenient and saves man hours. |  | Vacuum recovery deviceThe vacuum recovery device uses the hopper, ceramic horizontal pipe and riser fixed at the end of the scraper to convey powder, granular and small pieces of bulk materials upward. It is composed of solenoid valve, vacuum pipe, vacuum device, vacuum pump, etc., which is convenient for installation and simple in structure; The vacuum ceramic tube is made of ceramic, with good wear resistance and sealing performance. The vacuum device is made of stainless steel by welding, and it is equipped with an access door, which can repair and replace internal components; The vacuum pump is designed on the ground and is connected with the vacuum device by pipeline for vacuum pumping. It is more conducive to maintenance and cost reduction. |

The scraper vacuum recovery sandblasting room uses our company's 6th generation sand dust separator, which is specially used for accurately screening and separating sandblasting abrasives. It can finely screen and separate abrasives or shot materials of various types and arbitrary particle sizes, control the abrasive particle size at will, and ensure that the abrasive particle size recycled is completely uniform, so as to ensure the quality and efficiency of high-precision sandblasting and save abrasives. Through secondary screening, foreign matters, debris impurities, unqualified abrasives, broken fine abrasives and fine debris are separated, and only good Abrasives required by the process are recycled back to the spray gun. |  |

| The cartridge filter is adopted, which has high efficiency, large filtering area, low filtering wind speed and small resistance, so as to ensure the efficiency and service life of the filter, and ensure that the dust content discharged into the atmosphere under various working conditions meets the integrated emission standard of air pollutants (GB16297-1996). The filter cartridge adopts new materials produced in Japan, and its filter material is 100% polyester fiber, with a thickness of 0.75mm; Maximum heat resistance: 80 ℃; Air permeability: 220m3/m2/h; Weight: 240g/m2; Filtration accuracy: 5um-10um; Filtration resistance: ≤ 45pa; Filtration efficiency: ≥ 99.99% |

The electric control system of scraper vacuum recovery sandblasting room adopts S7 Series Programmable controller produced by German Siemens company for centralized control, which has the characteristics of fast information processing speed, stable and reliable performance, and more convenient communication networking. Contactors and thermal relays are made by Schneider of France, and switches and indicators are made by Fuji of Japan. The customers of the conveying system can choose by themselves according to the actual situation. |  |

|  |  |  |

The modular replacement of grille is convenient | Explosion proof lamp, durable and comfortable | Sandblasting clothes for healthy and efficient operation | Rubber plate prolongs housing life |

| Number | Project name | unit | Parameters / specifications |

|---|---|---|---|

| 1 | Empty size in sand blasting room | mm | 20000*4000*4000 |

| Housing form | Through type | ||

| Gate size(W x H) | mm | 3000*3000 | |

| Gate form | Electric liftgate | ||

| Safety door size(W x H) | mm | 800*1900 | |

| 2 | Sandblasting system / model | JT-11-900 | |

| Diameter of sand storage tank | mm | 900 | |

| Volume of sand storage tank | m³ | 1 | |

| Number of spray guns | 把 | 2 | |

| Nozzle diameter | mm | 10或12 | |

| Sand blasting efficiency (single gun) | m²/h | 15-25 | |

| Sand blasting volume | kg/h | 0-2200 | |

| Gas consumption | m³/min/单枪 | 6-9 | |

| quantity | 套 | 2 | |

| 3 | Sand particle size | mm | Φ0.2-1.2mm |

| Sand type | Steel sand | ||

| First addition | kg | 16000 | |

| 4 | Surface cleaning grade | SG8923-88 | Sa2.5 |

| 5 | Surface roughness | mm | 20-50 |

| 6 | lighting | ||

| Ceiling lamp type | Philips metal halide lamp | ||

| quantity | Calyx | 14 | |

| power | KW | 14*0.25=3.5 | |

| 7 | Abrasive recovery system | Scraper conveying + bucket lifting | |

| 8 | Scraper recovery system | ||

| 9 | Sand dust separator | Set | 1 |

| Sorting principle | Three stage separation | ||

| Sorting granularity | Stepless adjustable | ||

| Sorting capacity | T/h | 6 | |

| 10 | Dust purification system | SEt | 2 |

| Treatment air volume | m³/h | 4000 | |

| filtration velocity | m/min | 0.4-0.8 | |

| Filtering method | Cartridge filtration | ||

| Ash removal method | Pulse blowback | ||

| Air consumption for ash cleaning | m³/min | 1.5-3.5 | |

| Dust removal efficiency | 99.99% | ||

| Fan power | KW | 45 | |

| 11 | Air conditioning sandblasting suit | Set | 2 |

| Air pressure | MPa | 0.4-0.7 | |

| Temperature regulation range | ℃ | 10-40 | |

Note:

1.the dimensions of the equipment are for reference and can be designed and manufactured according to the dimensions of customers' products.

2.If you want to customize it, you can click this text

1. Within 20 working days from the effective date of the contract, the supplier shall provide the basic process diagram, system diagram and layout plan of the equipment;

2. Production time: 60 working days;

3. The installation and commissioning time is 60 working days;

1. The warranty period of all products produced by our company is 1 year.

2. During the warranty period, if the equipment is damaged due to quality problems, Party B shall repair it free of charge.

3. In case of damage caused by Party A during the warranty period, Party B is obliged to maintain it in time and only charge appropriate costs.

After the expiration of the warranty period, the maintenance of the equipment shall be provided by the supplier, and the supplier will only charge the cost of replacing parts, and will not charge other fees.

5. The supplier has strong logistics support ability, has certain spare parts and vulnerable parts, and can provide them to users in time.

1. If there is a problem with the equipment during work, we will call or fax to guide the maintenance within 4 hours;

2. If the phone or fax cannot solve the problem, our maintenance personnel will arrive at the site within 72 hours;

3. After the delivery of the equipment, we pay a return visit to the users every six months to understand the use of the equipment.